In Estonia, the Optimatik G-24 grain mill manufactured by OLIS for processing buckwheat with a capacity of 24 tons per day has been successfully launched. “The launch of the Optimatik G-24 grain mill in Estonia is another successful case for Ukrainian mechanical engineering. We do not just export equipment, but set standards in the field of grain processing. Our technologies have already proven themselves in the international market and the trust of the EU, North America and the Middle East only confirms their effectiveness. We are actively expanding cooperation with European customers, supplying modern grain mills, Gorizont-K and PSO flat-screen grain cleaning separators, LUCH ZSO drum grain cleaning separators, laboratory equipment, etc., and this project, the implementation of which we began after signing the Ukrainian equipment, – noted Volodymyr Chehlatoniev, Deputy General Director for Commercial Issues at OLIS.

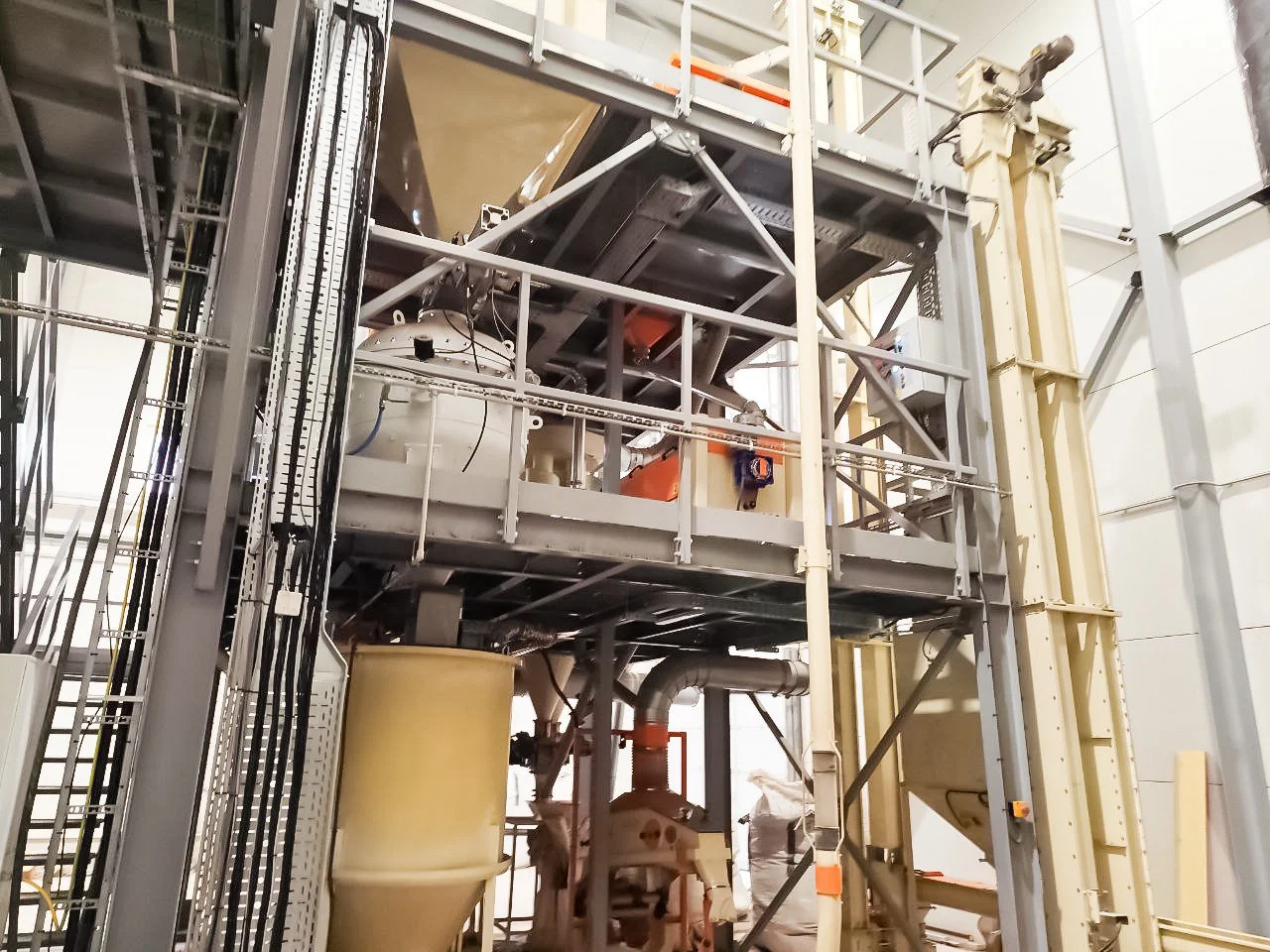

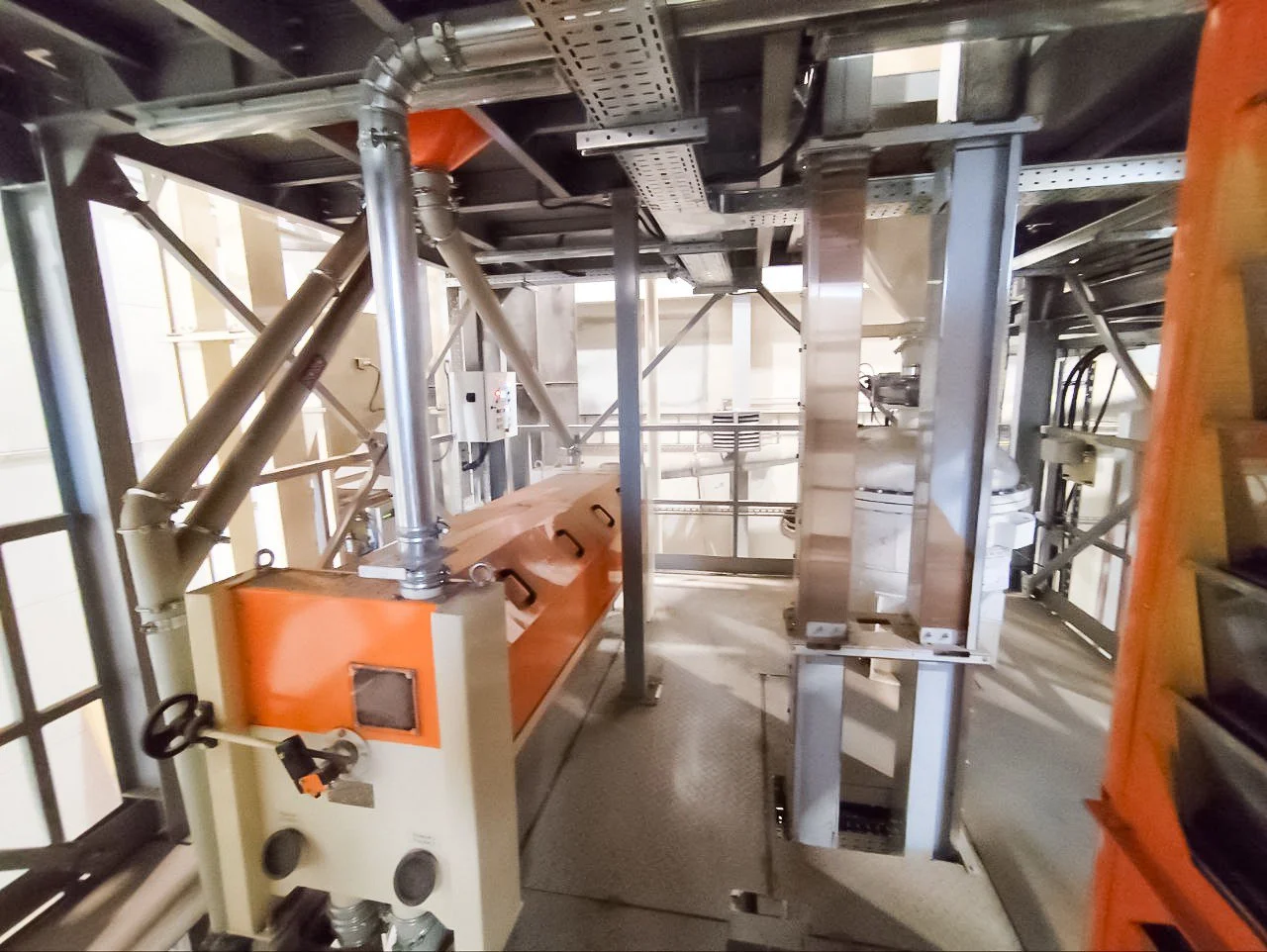

The customer received the Optimatic G-24 grain mill from OLIS – a set of technological equipment for processing buckwheat, including a metal structure, aspiration, gravity and pneumatic transport, electrical parts and automation.

The company’s technologists adapted the equipment to the architectural features of the customer’s production facilities and implemented multi-format packaging – from big bags to small packaging.

The Optimatic G-24 grain mill provides a high yield and quality of cereals among aggregate grain mills. An important advantage is the ability to produce both traditional steamed buckwheat – kernels, and unsteamed “green” buckwheat – without hydrothermal treatment, which opens up new opportunities for export to countries where the demand for healthy food products is growing. To date, the first stage of the line launch has been completed, allowing the production of unsteamed (green) buckwheat. Finished products have already appeared on the shelves of supermarkets in the European Union.

In the near future, it is planned to build a boiler house that will produce steam from buckwheat husks, which will allow us to obtain steamed buckwheat groats – buckwheat kernels.