Technology of production of grains – unpolished pea.

O.P. Vereshchynskyi, General Director of OLYS LLC, Doctor of Technical Sciences

O.V. Shevchenko, head of the development and implementation department of OLYS LLC, Odesa

As you know, the cotyledons in the pea grain make up 90-94% of its weight [1], but the actual yield of ground pea grains produced by traditional technology does not exceed 82-83% of the weight of the cleaned grain. At the same time, the yield of crumbs and flour is about 7-8%. In view of the indicated degree of use of pea grain for food, increasing the yield of groats is a promising direction for the development of its processing technology.

An analysis of the traditional technology for the production of pea groats [1, 2] shows that the formation of a significant amount of flour and crumbs is caused by peeling-grinding operations carried out in peeling-grinding machines. These machines realize the action of abrasion with an abrasive rotor, therefore the grinding of the cotyledon of the grain with the formation of crumbs and flour is a natural consequence of their work. Hulled peas, especially separated cotyledons, have a damaged surface, therefore, to improve the marketability of the cereal, these products are polished. The polishing operation is also carried out in peeling-grinding machines, but with much “softer” modes. However, the consequence of such processing is also the separation of parts of the cotyledon in the form of flour, which also leads to a decrease in the yield of grains.

The analysis of the morphology and anatomy of pea grain, as well as the traditional technology of processing it into groats, made it possible to substantiate the possibility of solving the problem of developing equipment and technology for the production of unpolished pea groats, which will be implemented without the use of shelling and grinding machines.

The result of design research was the development of MRG machine for peeling peas and splitting them into cotyledons . Structurally, the MRG machine is a horizontal rotor with whips and a sieve cylinder with longitudinal brake bars. The openings of the sieve cylinder are rectangular in shape, the long side of which is located perpendicular to its axis. Moving along the rotor under the action of the whips, the pea grain is subjected to shear and shock loads caused by the interaction with the whips and brake bars. This interaction leads to intensive peeling of the pea grain and grinding it on the cotyledon. The cotyledons formed are immediately removed from the working area of the machine by sieving through the openings of the sieve cylinder. Grains that have not undergone crushing are taken out separately from the sieve cylinder. It was found that for different batches of grain, in order to obtain the best results, it is necessary to set certain power loads, which is performed by adjusting the speed of rotation of the machine rotor. At the same time, an increase in power loads does not lead to peeling of poorly developed grains, which are usually part of the grain mass, and splitting them on the cotyledons. When a certain limit is reached, the destruction of such grains into pieces together with the seed coats is observed. Taking into account the difference in the size of full-fledged and poorly developed grains before processing in the MRG machine, a fractionation operation with the removal of a small grain fraction from the processing process is advisable. In addition, it was found that full-fledged pea grains (Fig.1) in their mass, they always differ in their strength before crushing on the cotyledon and in the strength of attachment of their shells. Based on this, processing regimes that ensure the minimum amount of formation of crumbs and flour should provide for selective force action on grains that differ in strength characteristics. The mentioned condition can be achieved by the appropriate technological scheme of processing, which provides for repeated processing of the step fraction of the machine.

Fig. 1 Pea grain

It should be noted that during processing in the MRG machine, the flower shells of peas are separated while maintaining a spherical shape (Fig. 2), have a low hanging speed and are effectively removed in aspirators of any design.

Fig. 2 A pea pod separated in an MRI machine

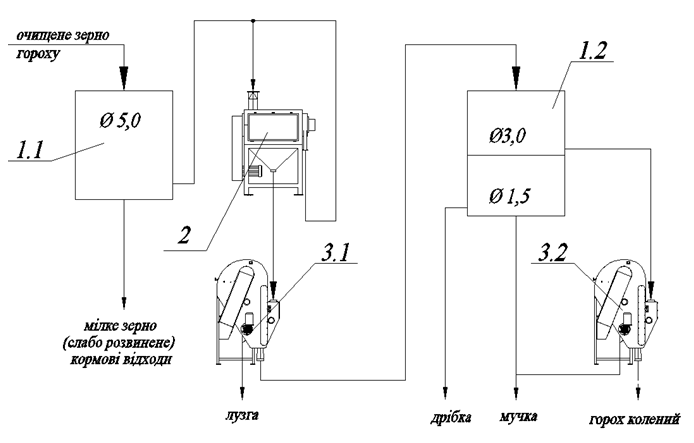

On the basis of the above research results, a technological scheme for the production of unpolished knee peas was developed (Fig. 3). The production test showed that the output of groats from peas produced according to the given scheme is 3-4% higher than when using traditional technology. In terms of appearance, the obtained cereals are significantly different from cereals produced using traditional technology. A smooth, glossy surface of the grains without traces of damage gives the groats an improved marketable appearance (Fig. 4).

Fig. 3 Basic technological diagram of the production of groats from unpolished peas. 1-dispersed; 2-MRI machine; 3-aspirator

Fig. 4 Unpolished knee peas

Thus, based on the results of the work, a new technology for processing pea grains into cereals, a technological scheme and equipment for its implementation are recommended. Two models of MRG machines with a capacity of up to 1.5 t/h have been developed and put into production. and up to 3.0 t/h. (www.olis.com.ua). The implementation of the mentioned technology allows to significantly increase the yield of groats from peas, as well as to produce a new type of them – unpolished knee peas.

Literature:

1. Kroshko G.D. Rules of organization and management of the technological process at grain factories. [Text] / G.D. Kroshko [etc.]. – K.: Vipol, 1998. – 145c.

2. Shutenko E.I. Cereal production technology [Text] / E.I. Shutenko, S.M. Soc. – K.: Education of Ukraine, 2010. – 272 p.