Vereshchinsky A.P., OLIS LLC, Doctor of Technical Sciences

According to long-term experience of operation of aspiration systems at grain processing enterprises, their operability and efficiency are largely determined by the reliability of sluice gates (Fig.1), which are part of air cleaning devices. In most cases emergency situations are characterised by increased dust emission into the atmosphere during cyclones operation, reduction of filters productivity as a result of insufficient degree of regeneration of their filtering surface, periodic clogging of the inner cavity of cyclones and filters with dust. However, the most painful case is frequent jamming of sluice gate rotors, which leads to forced stoppage of the whole aspiration transport and technological system (ATTS).

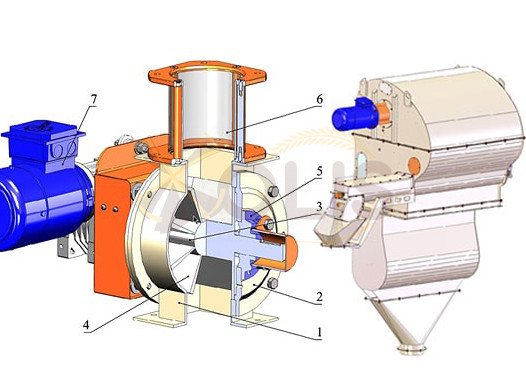

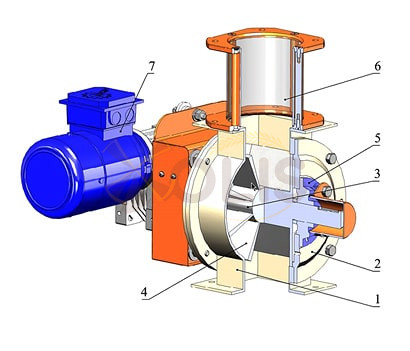

Figure 1 Sluice gate.

1 – housing; 2 – housing cover; 3 – rotor;

4 – rotor blades; 5 – bearing unit;

6 – transparent insert; 7 – actuator.

In most cases cyclones and filters are installed on suction branches of aspiration systems, which causes air rarefaction in the internal cavity of these devices. On this basis, the sluice gates are designed to ensure that the dust separated in the device is discharged outside, while ensuring a sufficiently high degree of tightness with respect to air, which is achieved by tight fitting of the mating surfaces of the rotor and housing. It is considered that the case and the rotor are fitted satisfactorily, if at rotation of the rotor the rotor blades in a gap between the case confidently cut a strip of paper! Increase of the said gap as a result of poor quality manufacturing of the sluice gate or due to abrasive wear of the mating surfaces disturbs its tightness. As a result, an upward air flow rushes through the sluice gate to meet the discharged dust attitudes and is sucked inside cyclones or filters. At the same time, it is characteristic of dust attitudes hovering over the airlock and their return, which is clearly visible through the transparent insert, if the device is equipped with such. Dust drift into the cyclone cavity reduces its cleaning coefficient (cyclone dusts), and dust drift into the filter cavity promotes its sticking on filter bags, increases aerodynamic resistance of the device and, as a consequence, reduces its productivity. In addition, the hang-up and return of dust attitudes is the root cause of clogging of the inner cavity of cyclones and filters. In this case, all dust inclusions coming with aspiration air into the cyclone are discharged into the atmosphere, and the filter resistance increases up to stopping of aspiration air flow. To avoid these accidents, airlocks with a high degree of tightness should be used and replaced in a timely manner as they lose their tightness due to abrasion.

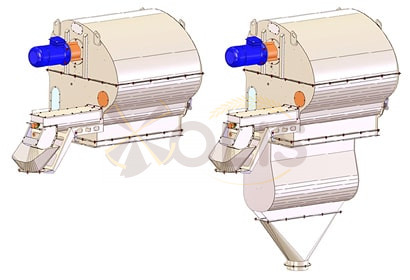

I – WHS; II – WSM.

Figure 2 Closed-circuit air separators.

Causes of jamming of sluice gates can be violation of alignment of rotor and housing due to inaccurate machining or wear of seating surfaces of the device, development of bearings, penetration of mineral impurity (sand) between mating surfaces of rotor and housing, as well as solid large formations in rotor cells. Especially vulnerable at elevators are sluice gates with friction bearings designed for use in pneumatic conveying systems of mills conveying grain milling products that do not contain mineral impurities. Under conditions of highly abrasive elevator dust, the friction bearings wear rapidly, causing the sluice gate to fail. The movement of mineral-rich aspirating attitudes through sluice gates on elevators is a natural process. Therefore, the ingress of solid particles between the rotor blades and the housing, often resulting in their jamming, is inevitable. However, this probability can be significantly reduced. The use of pneumatic separators with closed air cycle of VSZ and VSZM types for grain cleaning from light impurities (Fig. 2) excludes the necessity of cleaning of huge technological volumes of air with high concentration of impurities, including mineral impurities. Aspiration volumes of air are insignificant in comparison with technological air volumes, besides the dust contained in them, as a rule, is finely dispersed and does not lead to rotor jamming. Thus, the use of pneumatic separators with a closed air cycle reduces the number of cyclones and filters required many times and also provides favourable conditions for the operation of sluice gates.

Appearance of solid large formations in the cavity of cyclones and filters is observed due to accumulation of dust attitudes there, moisture condensation and precipitation inflow. In order to exclude accumulation of dust attitudes, ATTS operation without aspiration start should be blocked. Even at stopped fan of the aspiration system due to ejection and convection processes dusty air streams generated by transport and technological equipment penetrate through aspiration ducts into the cavity of cyclones or filters forming dust deposits there. The prevention of dust deposits accumulation in the cavity of cyclones and filters is facilitated by the correct order of ATTS equipment start-up and shutdown, as well as by cleaning of these devices each time immediately before start-up and immediately after shutdown. When starting the ATTS in the automatic mode, first of all the sluice gates of filters and cyclones are started, after waiting up to 30 s – the device for regeneration of the filter surface of filters, then after waiting up to 30 s – the aspiration fan, after full start-up of the fan – transport and technological equipment. When stopping the ATTS, all the listed devices should be stopped in the reverse order, observing the appropriate time intervals. Heat insulation of air ducts, cyclone and filter housings contributes to prevention of moisture condensation, especially in case of their location in open areas. The cyclones and filters must be securely covered and the external ducts must be sealed to prevent precipitation.

There are known cases, when as a solution for elimination of frequent emergency stops due to jamming of the sluice gate the rotor surface grinding is performed. This measure, although leads to some reduction in the threat of jamming, but entails a significant reduction in the tightness of the sluice gate and deficiencies in the cyclone or filter operation described above.

Fig. 3 Rotor with blades with interchangeable elastic elements.

1 is the rotor blade;

2 – replaceable elastic element.

A number of manufacturers have recently produced sluice gates in which the rotor is formed by blades with replaceable elastic elements (Fig.3). Such sluice gates do not require the use of cast iron casting and its precise machining, and when the elastic elements wear out, they are replaced. Sluice gates of the described design are cheaper and much more durable than traditional ones. The use of elastic elements provides resistance to jamming of such sluice gates in case of mineral impurities, although it makes them more vulnerable in case of ingress of large solid formations due to the threat of breakage of elastic elements and deformation of rotor blades. Our tests have shown that such sluice gates are significantly inferior to traditional ones in terms of tightness. However, the design of sluice gates with elastic elements should be recognised as promising, although with a limited area of application. Such sluice gates can be used in case of coarse aspiration slopes represented by crop residues, spoilt grains, weed seeds, etc. Such sluices must be free of fine dusty particles, which pose a risk of hanging and backflow.

As follows from the above, the key to reliable operation of sluice gates as part of cyclones and bag filters is the correct design, arrangement and operation of ATTS elevators, the use of high quality sluice gates, their timely repair and replacement.