Ltd “Olis”

Vereshchynsky A.P., Ph.D.

«Grain storage and processing»- № 5, 2002

In the article “Efficient processing – the main factor promoting of soriz” (Journal Storage and Processing “, # 1, 2002), we have presented problems in grain production from corn of soriz, solutions and results. However, some portions of this study will gain a deeper extension and wider use, because affect the basic processes of processing of other cultures. By such processes include the operations peeling, grinding grain, conducted mainly in machines abrasive impact. Understanding the set of actions to develop cereals as purposeful redistribution of anatomical parts of the grain, gives grounds to consider the processing of its surface as one of the most powerful tool for influencing the efficiency of production as a whole. Contained and is the main argument, confirming the relevance of the material presented below.

Over the past few decades, both in Ukraine and abroad, and the only common core design of machines for peeling – grinding grain are machines of the type A1-ZSHN. Although these machines are designed for processing of barley, wheat and peas, they are used and the processing of other cultures. The relative simplicity and versatility of design has led to mass production of its various enterprises in its improved form. Nevertheless, the results of our testing of these machines show that this type is characterized by significant deficiencies inherent in traditional design-ZSHN A1-3. Analysis of the structural features of these machines has shown that there is still problem “improvement” amounted to the creation of machines with low productivity, and structural differences are determined mainly by technical manufacturing capabilities of an enterprise.

The main disadvantage of machines of this type is low efficiency of peeling – grinding is accompanied by high specific power consumption. Quality assurance is achieved by processing multiple forced many passes (two to six), number of used cars, and power consumption while may exceed more than half of the required on all production of cereals. In addition, to ensure the simultaneous operation of a specified number of vehicles requires the development of transport, aspiration, and other communication, which is associated with significant cost of capital for their creation, operation and maintenance.

One example of this is that at the stated in the passport productivity of 3 t / h actual performance ZSHN A1-3 on development of barley or soriz groats (the need for five – six passes) is in the range 250 – 300 kg / h in terms of one machine. Thus, the energy consumption only peeling – grinding one ton of grain is about 80 kW!

However, analysis of work machines such as A1-ZSHN, we carried out a number of parameters showed that the main reason for their shortcomings may not is the rational organization of the used modes of treatment. The foregoing has necessitated a better understanding of our patterns of flaking, grinding process, as the prospect of high-efficiency equipment to create a new level.

In these purposes, we performed a series of experiments using a specially crafted gollendr with replaceable working elements and the ability to work both in periodic and continuous modes. The studies conducted to study regularities of peeling-grinding various types of grain with different kinematic and force characteristics of systems: the product – air – the working bodies.

It should be noted that the criteria for assessing the quality of grain processing have been selected:

- Factor treatment k (%), defined as the difference between the masses of the source and the processed product, referred to the mass of the initial product;

- The degree of equalization of the processed product, determined visually.

The need for applying the criteria, due to the fact that the scaling factor in the traditional sense it is too subjective for handling attrition. In addition, the division of grains milled and milled does not fully reflect the degree of processing is significant, particularly for barley, wheat, soriz.

A considerable amount of studies does not allow their presentation, and the more detailed analysis within this article. In this regard, we present only the main findings, indicating the direction of our future design work.

- Among the important parameters affecting the magnitude of the values of k, should be included: the processing time difference between peripheral speeds of the rotor and the product (U), the product concentration in the chamber (Q), defined as the ratio of product mass in the chamber to its volume, living space and grit abrasive surface of the rotor. Dependence of k on each of these parameters at fixed values of the other close to the line.

- In turn, the value of U depends on a number of design parameters among which the most effective is the resistance (roughness) sieve shell (cylinder). However, even for fixed design parameters, there is always the dependence U = f (Q). Form of this dependence is shown in the figure and characterizes the influence of constraint conditions on the processes of energy transmission and distribution of the drive.

Figure. Graphs of k = f (Q), U = f (Q), N = f (Q). - With the dependence U = f (Q), real peel dependence k = f (Q) has the form, as shown in the figure. Increased values of Q leads to an increase in clamping force of the product to the rotor, and hence the intensification of wiping effects (bottom portion of the curve). Naturally, that higher values of k increments characteristic regions of increasing U. However, the values of Q close to the bulk mass of the product loses mobility and maximum abrasive effect, typical for such a regime, fall on the border to the working surface layer of the product. K value decreases sharply as part of the product is not processed, and the energy consumption is driving most of the costs, wear and heating of the boundary layer.

- Privedennye above regularities are confirmed by the character depending on the specific power consumption of the drive N on the concentrations of Q, N = f (Q), as shown in the figure. For values of Q close to the bulk mass of the product processes abrasion is accompanied jamming, causing noise, vibration, and hence additional energy dissipation as evidenced by the sharp rise in values of N.

- Analiz graphs given in the figure indicates the existence of the most rational values of Q (segment A-B) in terms of maximum and minimum values of k N. Thus, the regimes most favorable work peeler predetermined appropriate range of values of Q.

- Ochevidno that the interaction of particles of loose product with a working surface of the rotor is probabilistic in nature. Consequently, the intensification of mixing of the product in a radial direction to the work surface of the rotor leads to the homogenization of the total number of wiping contacts for each particle. Thus, the degree of equalization of the processed product depends on the intensity of the above mixing, defined by structural features of the rotor and sieve the shell, as well as the concentration value Q, which determines the condition constraint (p.3).

- Nepreryvnoe product movement along the axis of the rotor, from the loading to the discharge opening is an essential condition of the considered machine in a continuous loop. The difference between the total velocity of individual particles in the axial direction, caused by the presence of mixing, leads to different time of treatment, which negatively affects the degree of equalization of the processed product. Eliminating this effect is possible by a series of design activities to create a system of positioning of the product while it is moving in the axial direction.

The studies revealed that the design of machines such as A1-ZSHN allows their use only at concentrations close to the bulk mass of the product (segment B-D in the figure), at a reduced k values and high energy. In addition, such designs do not include measures control the mixing process, the relevant conclusions set out in Section 6 and 7. Indicated confirms the earlier result of inadequate machinery type A1-ZSHN caused by mismatch construction management, appropriate processes.

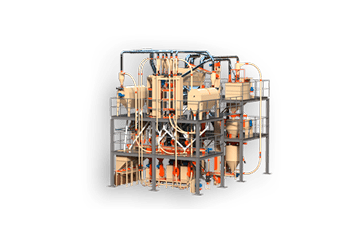

Based on the design of “Cascade”, we produce a range of machines with different performance.

All of the machines characterized by the absence of vibration and other dynamic forces at work, which eliminates the use of foundations as well as noise and dust emission in industrial premises. Moreover, we also design and have ergonomic ease of assembly – disassembly in case of replacement of wear of working bodies.

At the request of the customers cars can be equipped with feeders, control the magnitude of the load of the main engine. Such solutions are reliable and easy to ACS grinding plant schemes that allow to exploit the considered machine is completely automatic. In this case, the available mechanical adjustment act as trimming for adjustment to the required quality of peeling – grinding in the process of transition to another kind of grain.

Considered in this paper form of machinery refers to machines abrasive impact, although such an effect is always accompanied by shock, compression and shear. Made us work showed that by design changes the working bodies may substantially affect the value of any listed loads, providing the best conditions for processing the respective type of grain. At present, we completed work on the creation on the basis of design “CASCADE” high-peeling machines for millet and maize processing modes of dezherminator.