Vereshchinsky A.P. – Ph.D., (General Director of OLIS LLC, Odessa)

The issues of increasing the efficiency of varietal baking wheat grinding using grain peeling operations at the stage of preparation for grinding are considered.

Problem statement. One of the methods for increasing the efficiency of high-quality baking wheat grinding is the use of grain peeling operations at the stage of preparing it for grinding. Hulled grain is characterized by a reduced content of shells and germ, as well as reduced strength during grinding. The change in these properties of grain is proportional to the value of its peeling index and, during grinding, provides an increase in the yield of flour and an increase in its whiteness.

Main research results. Our research has established that the most rational, taking into account the quantitative and qualitative indicators of varietal baking grinding, is peeling of wheat grain in the range of peeling index values 6…8%. In order to study the possible effect on the chemical composition and baking properties of flour of changes in the technological properties of grain caused by its peeling to the specified values, the following studies were carried out.

Wheat grain (Table.1) conditioned according to existing recommendations [1], peeled in a laboratory flour, ground into flour with a yield of 70% on a laboratory installation MLU-202 and its quality indicators were determined (Table 2).

As can be seen from the data presented (Table 2), an increase in the level of peeling index k to 6% leads to an increase in ash content, whiteness and protein content in the resulting flour. When the hulling index k = 8, the ash content of flour decreases, taking values lower than in flour obtained from non-hulled grains (k = 0). The protein content at k = 8 also decreases slightly, and whiteness acquires the highest value.

Table 1. Wheat grain quality indicators

| Nature, g/l | 815 |

| Vitreousness, % | 55 |

| Ash content, % | 1.56 |

| Protein content, % | 13.4 |

| Gluten content. % | 24 |

| VDK indicator, conventional units | 70 |

| Number of falls, s | 302 |

Table 2. Quality indicators of flour with a yield of 70% and bread obtained from it

| Peel index k, % | 0 | 3 | 6 | 8 |

| Ash content, % | 0.62 | 0.63 | 0.65 | 0.59 |

| Whiteness, conventional unit. RZ-BPL | 58 | 58 | 59 | 60 |

| Protein content, % | 10.4 | 10.5 | 11.0 | 10.8 |

| Gluten content, % | 26 | 26 | 26 | 26 |

| VDK indicator, conventional units | 55 | 55 | 55 | 55 |

| Falling number, s | 332 | 370 | 382 | 392 |

| Water absorption capacity, % | 57.4 | 57.9 | 59.6 | 59.2 |

| Fractional composition, % more than 140 microns 140…125 µm 125…106 µm 106…95 µm less than 95 microns |

1 7 6 15 71 |

1 6 6 16 71 |

1 6 6 19 68 |

1 8 7 19 65 |

| Test baking of bread: volumetric output, cm³ porosity, % |

382 73 |

390 74 |

418 77 |

416 77 |

Taking into account the initial content of anatomical components in wheat grains and their chemical composition (Table 3), the following conclusion is obvious. Changes in flour quality indicators are caused by changes in the amount of aleurone layer entering its composition. It can be argued that the exposure of the aleurone layer by peeling promotes its grinding and entry into the flour composition, and this causes an increase in the ash content and protein content in it. A decrease in the content of shells in the grain with an increase in the peeling index provides: an increase in the whiteness of the flour. However, taking into account the quantitative relationship of the anatomical parts of wheat grains (Table 3), with an increase in the k value to 8%, the specific content of the aleurone layer in the grain also decreases significantly, which leads to a decrease in the protein content and ash content in flour. In addition, the above-mentioned increase in the peeling index k determines the minimum total content of shells in the grain, which also helps to reduce the ash content of flour, and the decrease in the content of pigmented seed coats ensures a further increase in its whiteness.

Table 3. Content of anatomical components in wheat grains and their chemical composition (in% of dry matter) [2-4]

| Anatomical parts | Content in grain | Protein | Starch | Raw fiber | Pentosans | Fats | Ash |

| Fruit shells | 3.0…6.5 | 5…8 | — | 20…22 | 25…30 | 1…2 | 3.5…24.5 |

| Seed coats | 1.1…3.54 | 12…20 | — | 1.0…1.5 | 14…36 | 0…0.2 | 7.0…20.0/td> |

| Embryo with scutellum | 1.5…3.0 | 24…42 | — | 2.0…2.5 | 9.0…11 | 13…24 | 5.5…6.5 |

| Aleurone layer | 6.8…8.8 | 16…20 | — | 5…7 | 6…8 | 10…15 | 14.5…17.0 |

| Endosperm | 77.0…80.0 | 12…15 | 75…80 | 0.1…0.2 | 2…3 | 0.7…1.0 | 0.35…0.5 |

As is known, the anatomical components of grain contain vitamins and microelements in proportion to the ash content. Thus, processing of hulled grain contributes to the use of the nutritional potential of the aleurone layer and, in the implementation of industrial grinding, can be a way to enrich high-quality flour with substances of natural origin. Unlike fortification with bran, the use of an aleurone layer does not pose the threat of reducing the consumer value and baking properties of high-grade flour.

The change in falling number and water absorption capacity of flour is obviously the result of a change in its chemical composition. The increase in flour coarseness, which is observed with increasing k value, is insignificant and is explained by a decrease in the load during grinding, which is ensured by a corresponding decrease in grain strength.

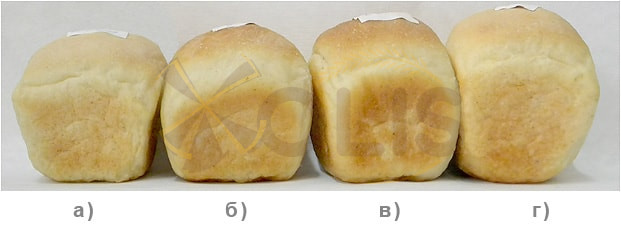

Flour made from hulled grain is characterized by improved baking properties; as can be seen from the results of test laboratory baking (Table 2 and Fig: 1).

Fig.1. Appearance of bread according to the results of test laboratory baking

a) k = 0; b) k = 3%; c) k = 6%; g) k = 8%

Conclusions. The obtained baking results confirm the trends established by studies of other authors [5-7], which were carried out in the range of peeling index values up to 5%.

- Kroshko G.D. Rules for organizing and conducting the technological process at boron mills [Text] / G.D. Kroshko [ta in.]. – K.: Vipol, 1998. – 145c.

- Romensky N.V. Chemical composition of wheat grain and its anatomical parts [Text] / N.V. Romensky // Proceedings of VNIIZ. – 1949. – Issue. 19. – pp. 21–49.

- Egorov V.A.Technological properties of grain [Text] / G.A. Egorov. – M.: Agropromizdat, 1985. – 333 p.

- Kazakov E.D. Biochemistry of grain and products of its processing [Text] / E.D. Kazakov, V.L. Kretovich. – M.: Kolos, 1980. – 319 p.

- Kondratiev A.I. Cleaning the grain surface at flour mills [Text] / A.I. Kondratyev, B.M. Maksimchuk / Series “Flour and cereal industry”: express information. – M.: TsNIITEI Minzaga USSR, 1977. – 40c.

- Dudarev I.R. Scientific and technical foundations of process intensification and the creation of machines for grain surface treatment [Text]: dis. … dr. tech. Sciences / I.R. Dudarev. – Odessa, 1989. – 437c.

- Galimzyanov D.A. Intensification of grain preparation for low-capacity mills [Text]: author’s abstract. dis. …cand. tech. Sciences / D.A. Galimzyanov. – M., 2010. – 26c.