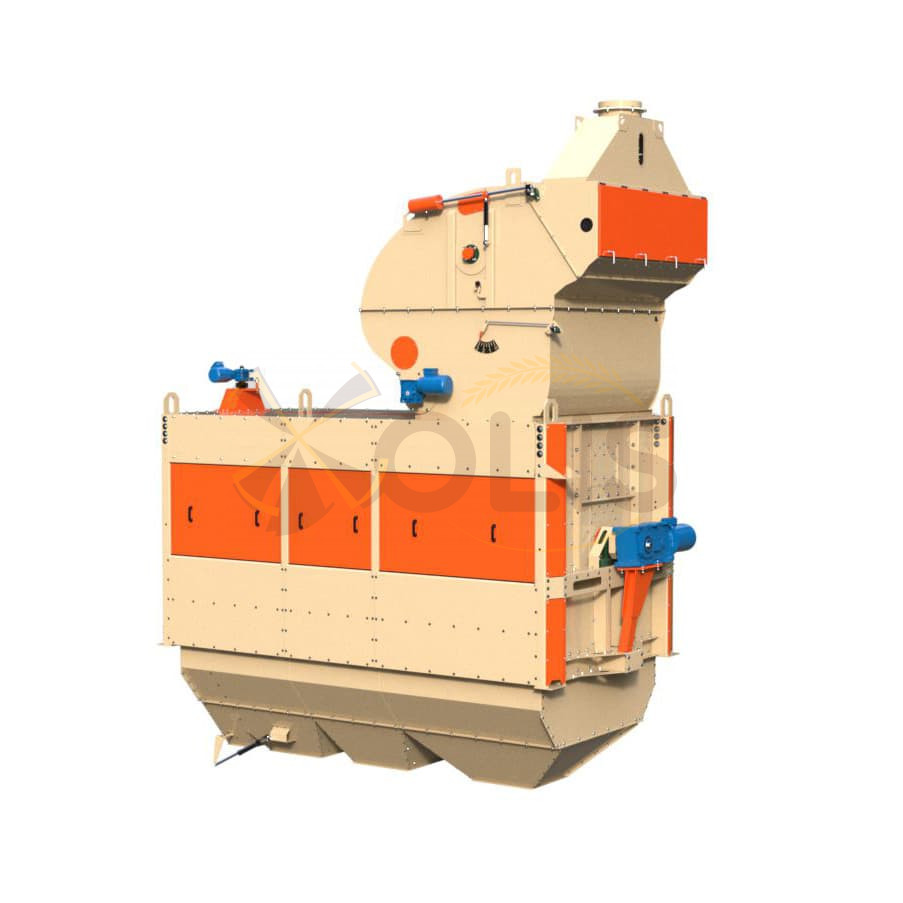

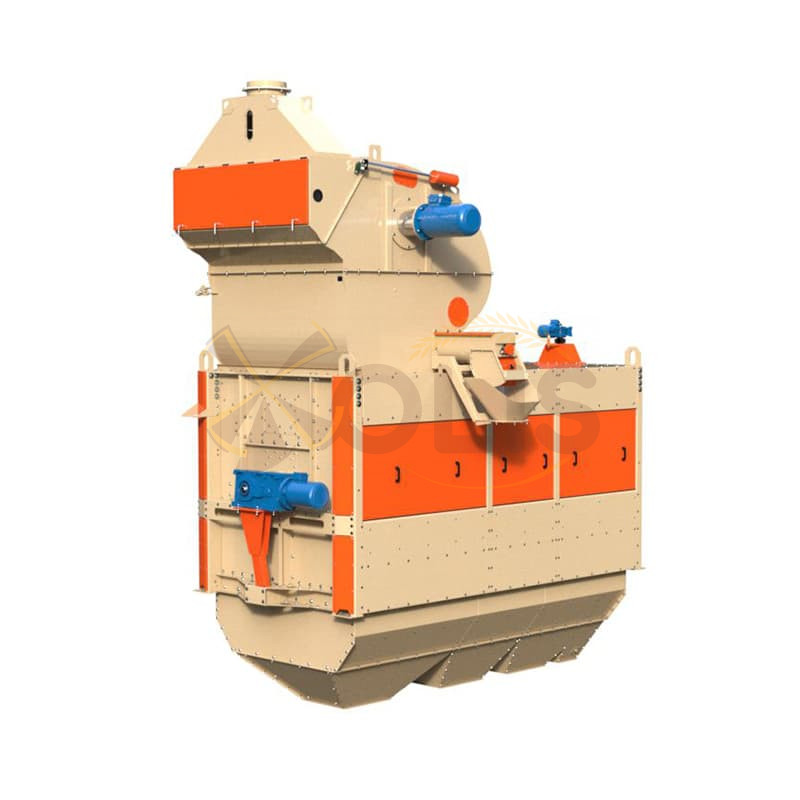

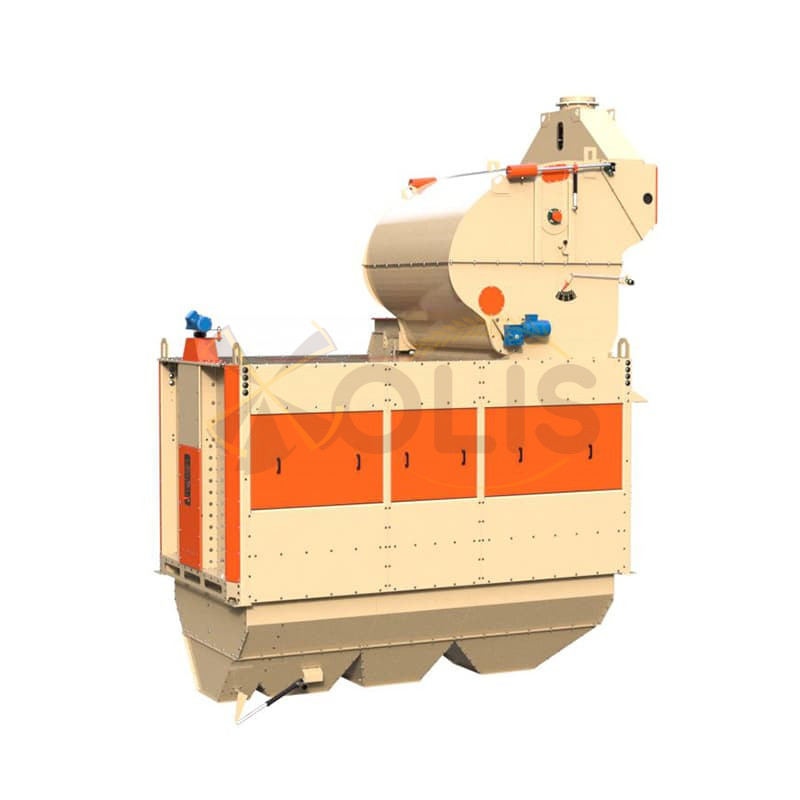

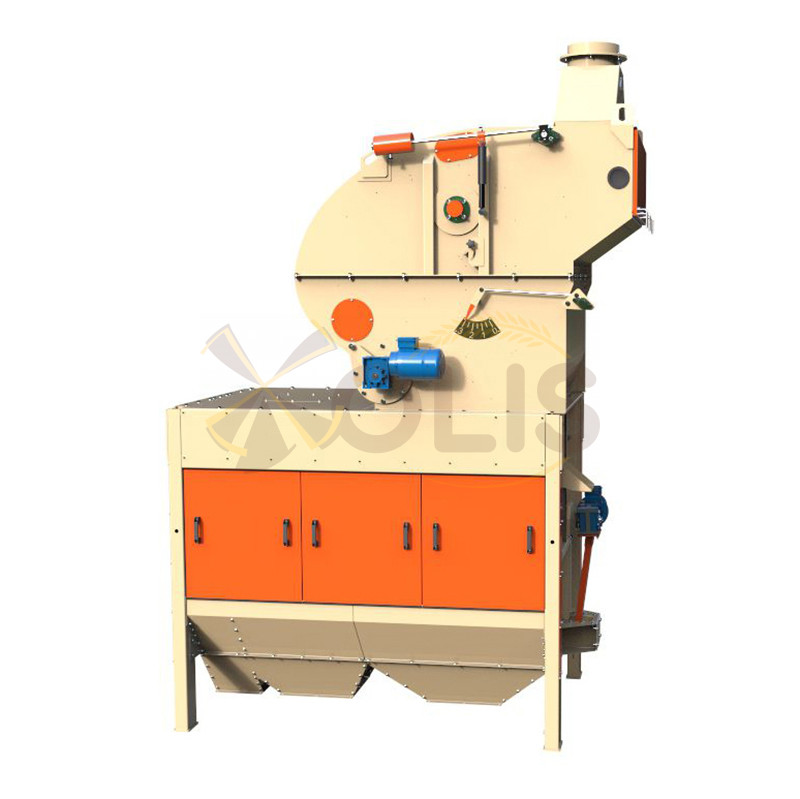

Rotary Drum Scalper SКО-300

Purpose:

Rotary drum scalper SКО-300 is designed for pre-cleaning – removing coarse impurities from grain. It is used in elevators and grain storages.

Description:

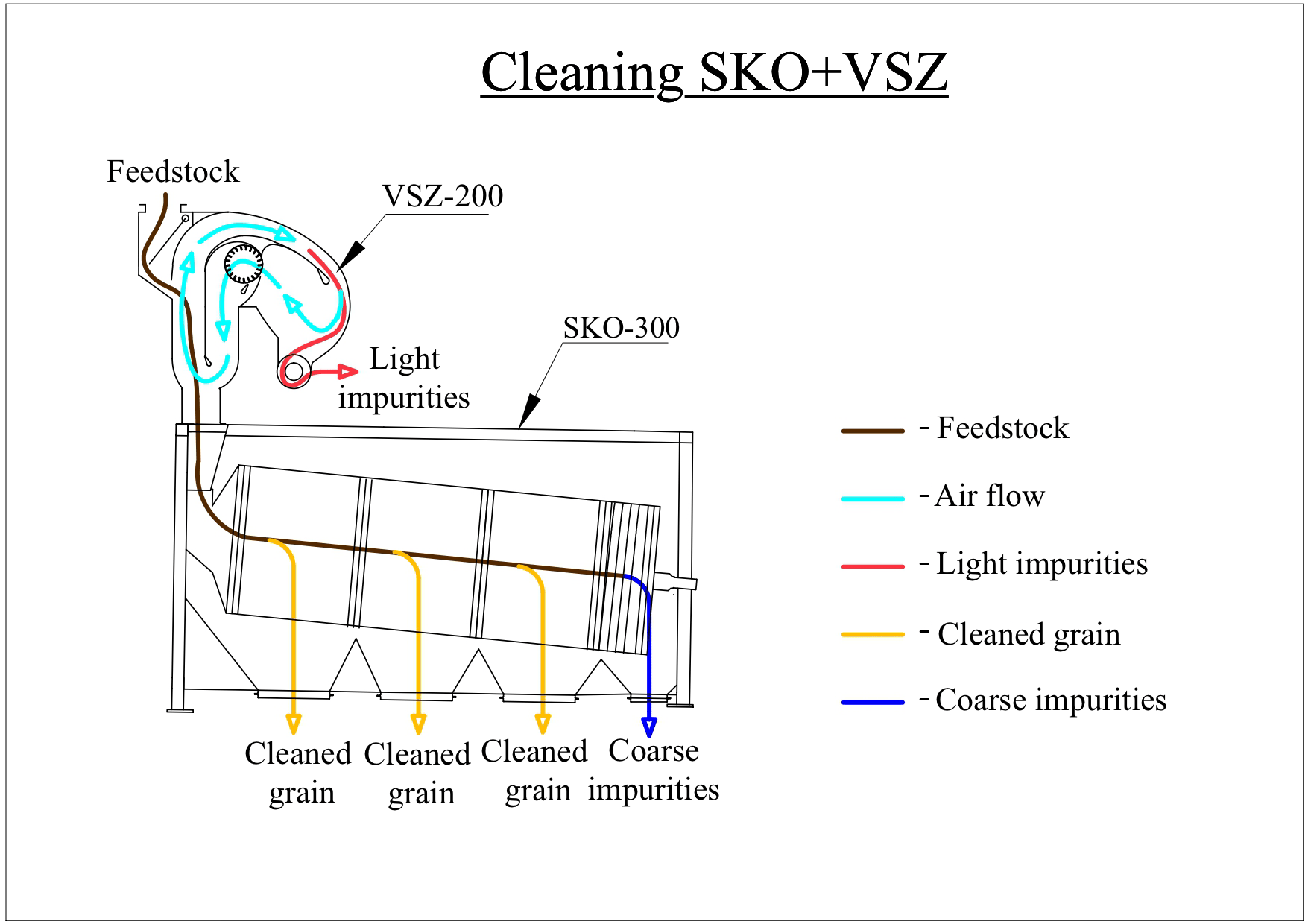

The initial product enters the drum, the sieves of which pass the grain and retain the garbage that comes out at the end of the cylinder. The use of the scalperator (pre-cleaner) is necessary to ensure normal during operation, prevent them from clogging and reduce energy consumption spent on drying the product, as well as for the selection of random objects that can lead to breakdowns of conveyance. Selection of the diameter of the perforated holes of the sieves depends on the processed grain, its moisture content and the type of impurities to be removed. If necessary, the first sieves can be used to remove fine impurities.

The scalperator can be equipped with an air separator (aspirator) with a closed air cycle VSZ, which is mounted on the skalperator on the grain separator LUCH ZSO principle.

In order to operate the grain cleaning scalperator with the air separator VSZ, it is additionally necessary to install the cyclone, a fan, the control panel and the air ducts.

To simplify installation work and for the most efficient operation of the skalperator, the company OLIS has developed an aggregate solution scalper SKO-300А.

Aggregate rotary drum scalper SKO-300А consists of: rotary drum scalper SKO-300, air separator with a closed air cycle VSZ, cyclone with sluice gate and drive, fan, ducts, control panel, cables, trays and ladders. (Fig. 2)

Specifications

| Model | SKO-300 | SKO-300А |

| Productivity up to, t/h | 300 | 300 |

| Pre-installed electric power capacity, kW | 22,5 | 29,00 |

| Diameter of the sieve drum, mm | 1900 | 1900 |

| Number of sections, approx. | 3 | 3 |

| Air consumption for aspiration, m3/h | 3000 | 5000 |

| Weight, kg | 5575 | 8230 |

| Overall dimensions*, mm length width height |

4915 2415 4040 |

6300 4875 5070 |

*- overall dimensions are indicated together with the air separator

Schemes of grain cleaning in the grain scalperator SKO-300

Аdvantages

- High technological efficiency due to the large area of the operating surface of the sieves and possibility of installing them independently depending on the specific operating conditions;

- Metal-bearing, wear-resistant construction;

- Adjustment of the angle of inclination of the drum, which expands the capabilities of the scalperator;

- Operational safety;

- Use of components from leading European manufacturers;

- Easy replacement of sieves of standard size that do not require finishing.

Photos

| Model | SKO-300 | SKO-300А |

| Productivity up to, t/h | 300 | 300 |

| Pre-installed electric power capacity, kW | 22,5 | 29,00 |

| Diameter of the sieve drum, mm | 1900 | 1900 |

| Number of sections, approx. | 3 | 3 |

| Air consumption for aspiration, m3/h | 3000 | 5000 |

| Weight, kg | 5575 | 8230 |

| Overall dimensions*, mm length width height |

4915 2415 4040 |

6300 4875 5070 |

*- overall dimensions are indicated together with the air separator

Schemes of grain cleaning in the grain scalperator SKO-300

- High technological efficiency due to the large area of the operating surface of the sieves and possibility of installing them independently depending on the specific operating conditions;

- Metal-bearing, wear-resistant construction;

- Adjustment of the angle of inclination of the drum, which expands the capabilities of the scalperator;

- Operational safety;

- Use of components from leading European manufacturers;

- Easy replacement of sieves of standard size that do not require finishing.