Screen Cleaner PSO-3

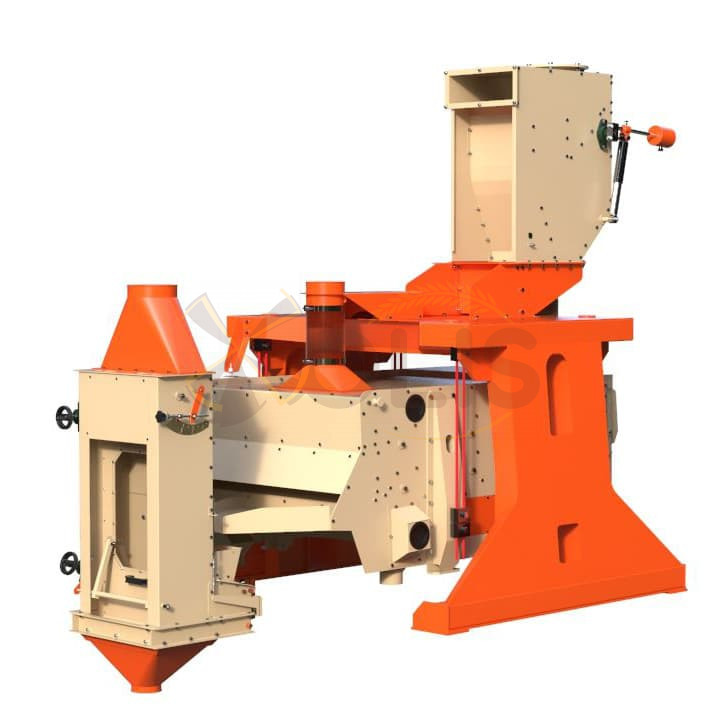

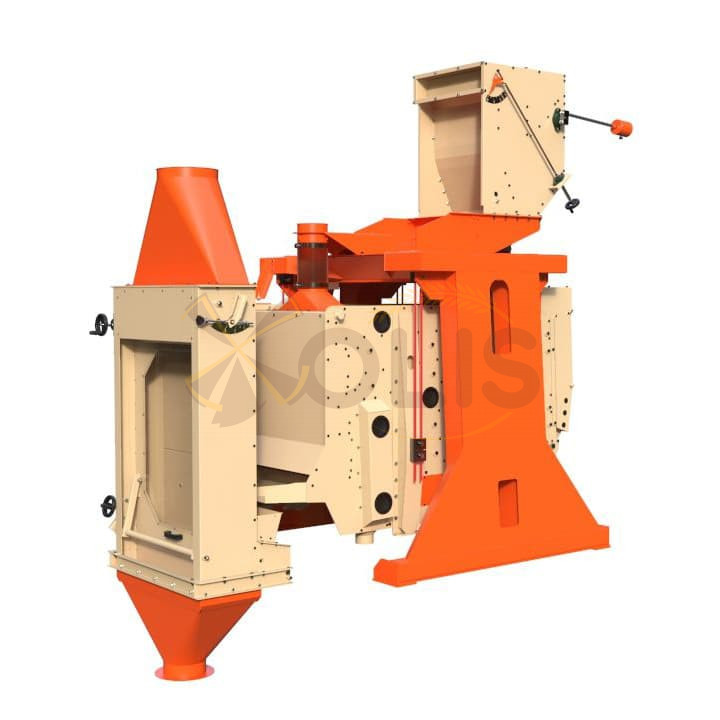

Screen cleaner flat-sieve type PSO-3 are designed for sorting and cleaning grain crops from impurities which differ from grain in geometric dimensions and aerodynamic properties.

Product video

Product Description

Specifications

Аdvantages

Video/Photo

Additional Information

Описание

Описание

Олис

Олис

Purpose:

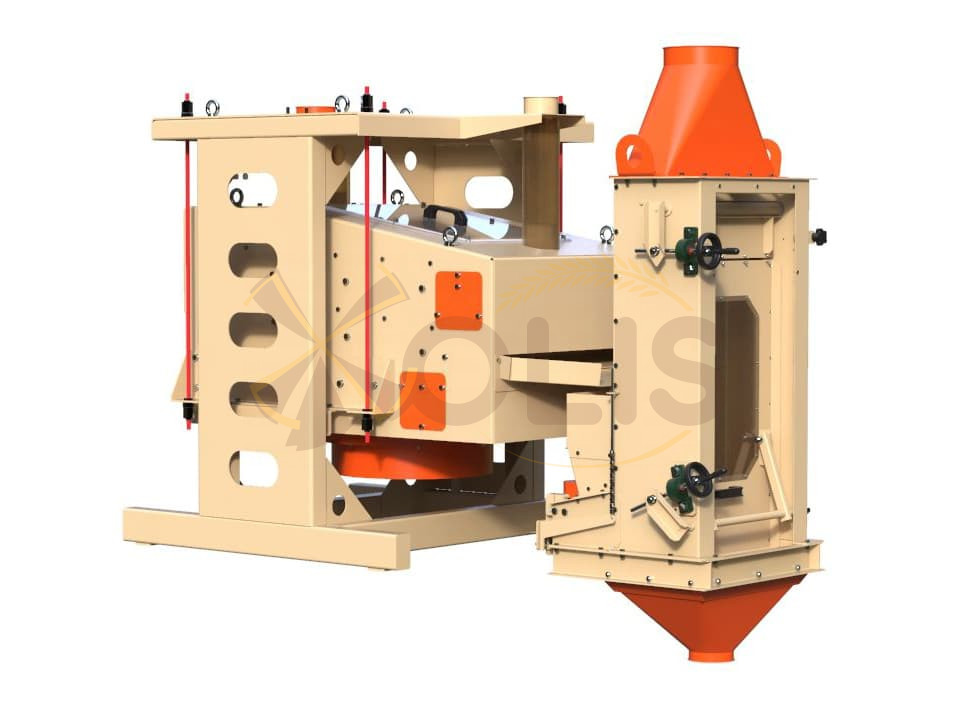

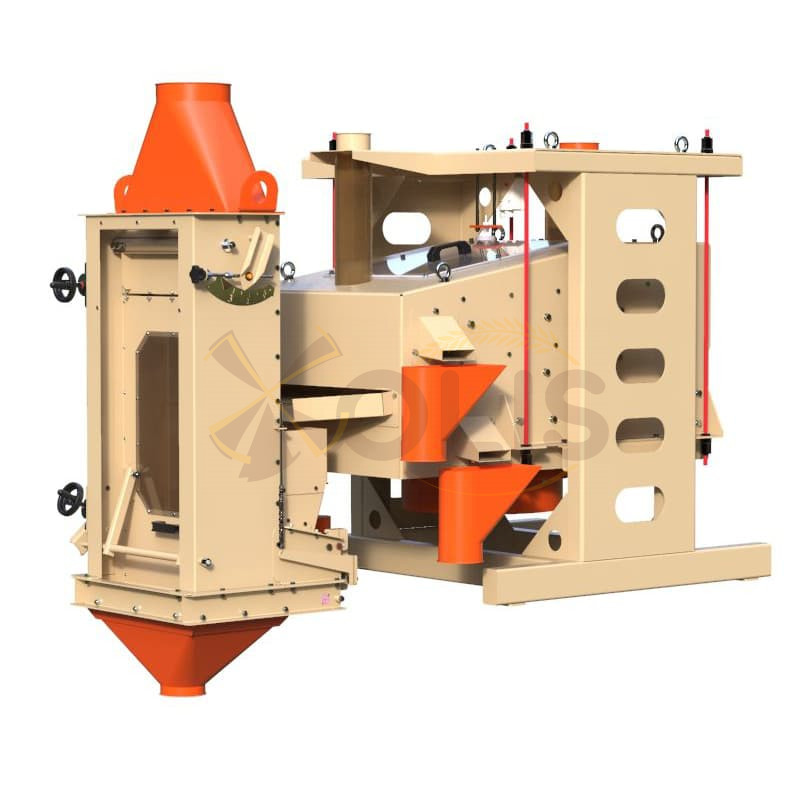

Screen cleaner flat-sieve type PSO-3 are designed for sorting and cleaning grain crops from impurities which differ from grain in geometric dimensions and aerodynamic properties.

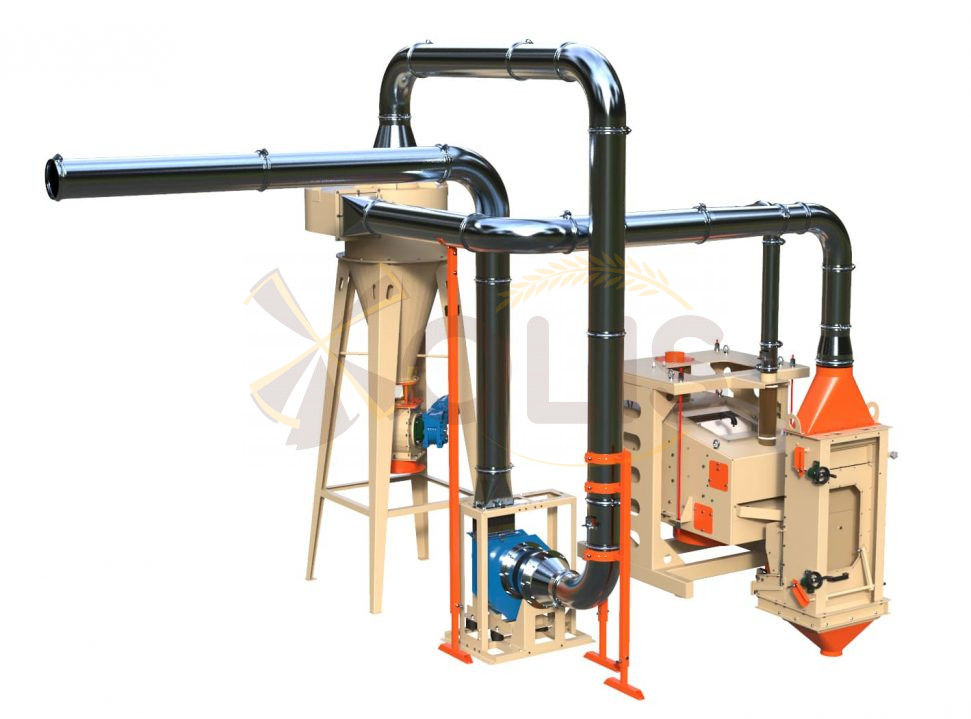

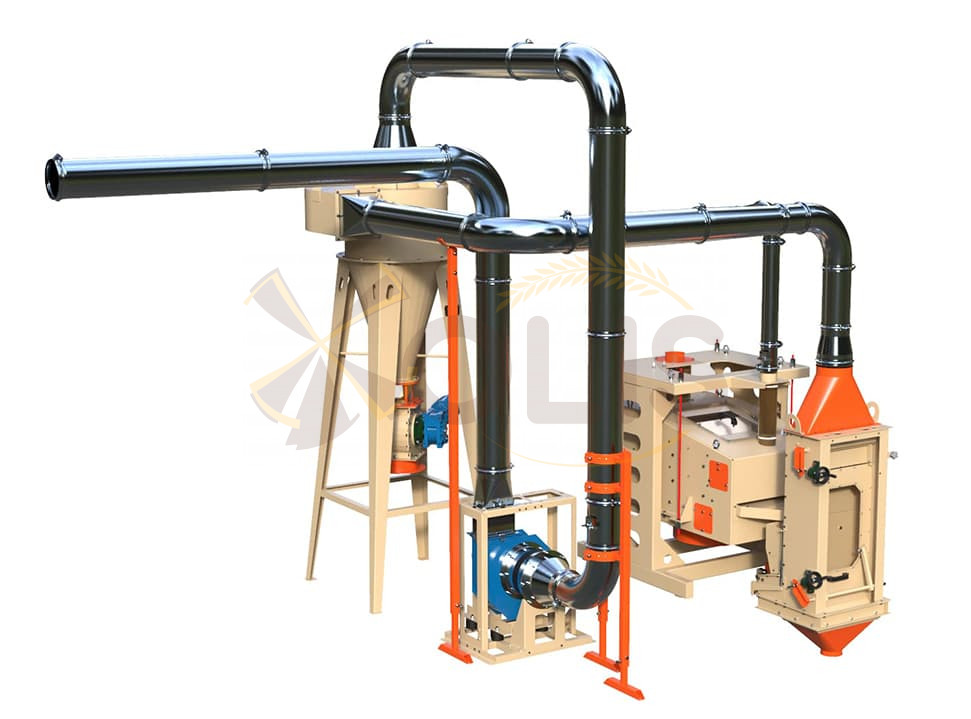

Screen cleaner flat-sieve type PSO-3 are equipped with an aspiration column КАО-0.6

To operate the screen cleaner PSO-3 with the aspiration column KAO-0.6, it is additionally necessary to install a cyclone, a fan, a control panel and air ducts.

To simplify installation work and ensure the most efficient operation of the flat-sieve type separator, the company OLIS has developed an aggregate solution PSO-3А.

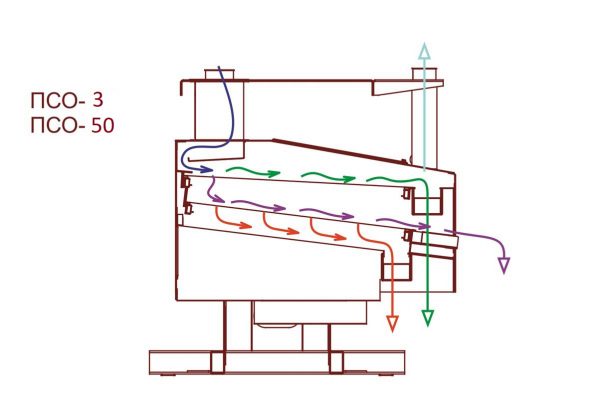

Scheme of grain cleaning in the screen cleaner PSO

Specifications

Выберите модель

| Model | PSO-3 |

| Preliminary cleaning, up to t/h | 12 |

| Primary cleaning, up to t/h | 3 |

| Air consumption, m3/h | 300 |

| Pre-installed electric power capacity, kW | 0,55 |

| Weight, kg | 425 |

| Overall dimensions, mm length width height |

1580 820 1220 |

Аdvantages

- Strong, durable construction;

- Installation symmetry of nozzles allows flexible installation of the separator in existing and new technological lines;

- Absence of contaminations;

- High efficiency of grain cleaning;

- Small dimensions;

- Ease of replacement of sieves and reliability of their cleaning;

- View of the pneumoseparation zone.

Videos

Photos

Выберите модель

| Model | PSO-3 |

| Preliminary cleaning, up to t/h | 12 |

| Primary cleaning, up to t/h | 3 |

| Air consumption, m3/h | 300 |

| Pre-installed electric power capacity, kW | 0,55 |

| Weight, kg | 425 |

| Overall dimensions, mm length width height |

1580 820 1220 |

- Strong, durable construction;

- Installation symmetry of nozzles allows flexible installation of the separator in existing and new technological lines;

- Absence of contaminations;

- High efficiency of grain cleaning;

- Small dimensions;

- Ease of replacement of sieves and reliability of their cleaning;

- View of the pneumoseparation zone.

Other goods in this category

X