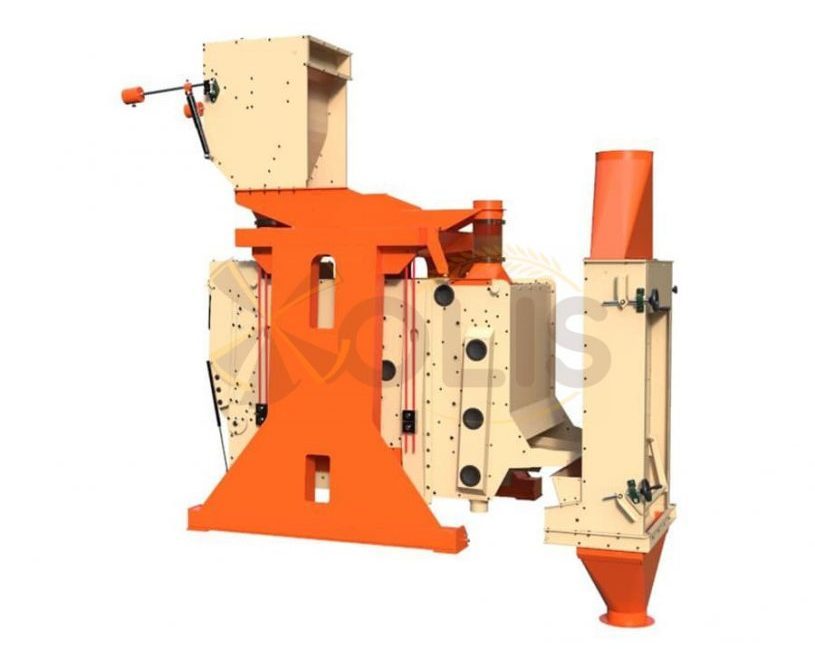

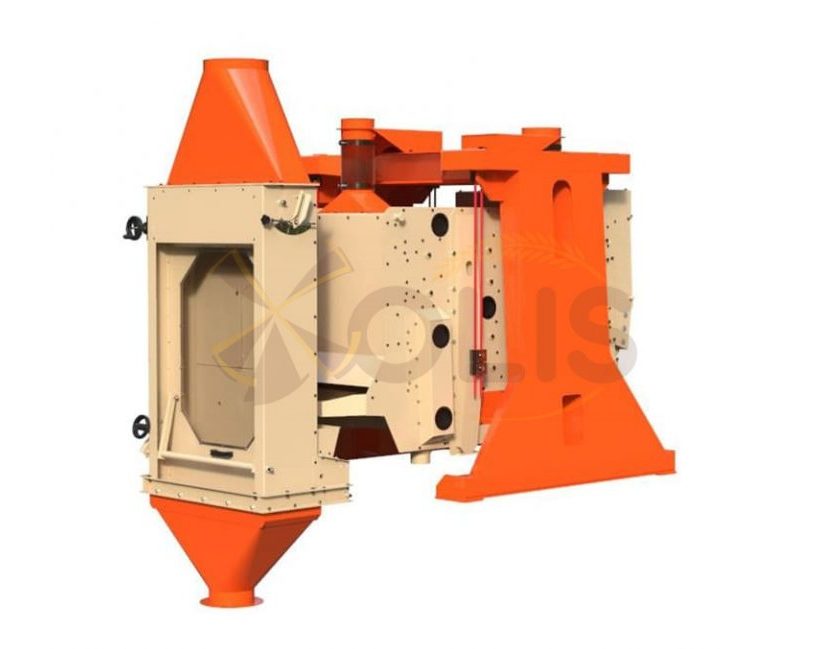

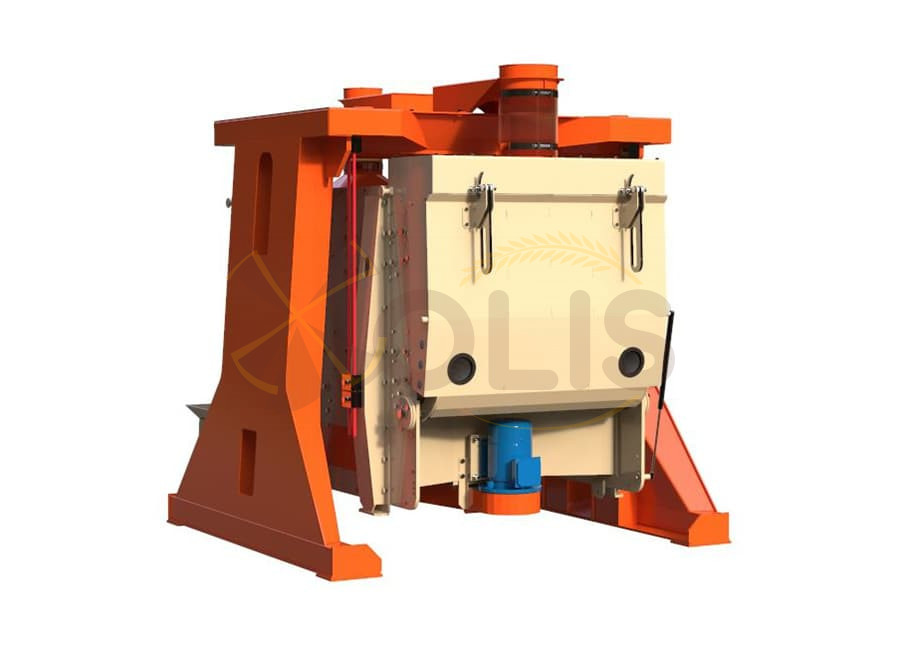

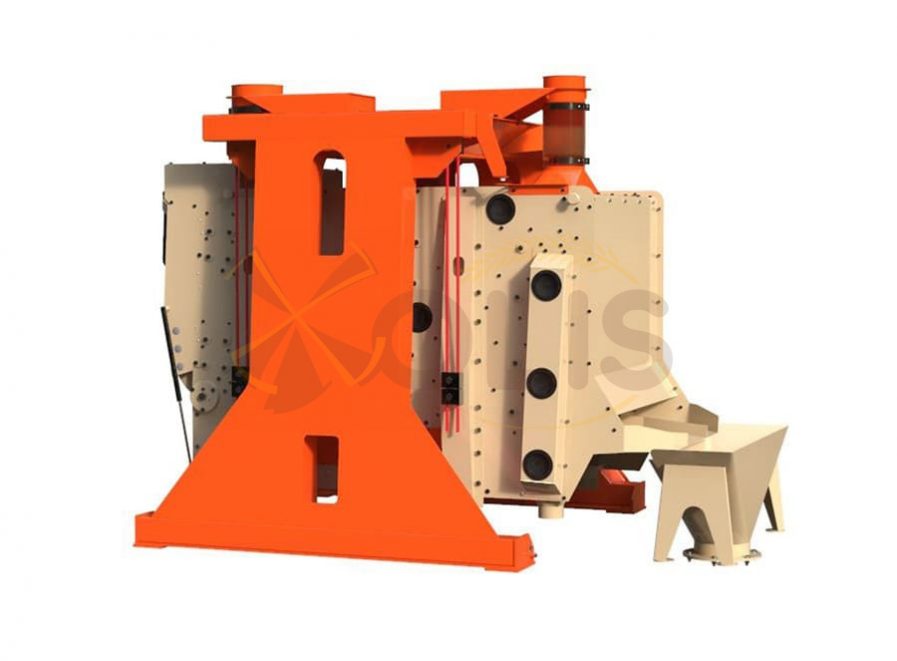

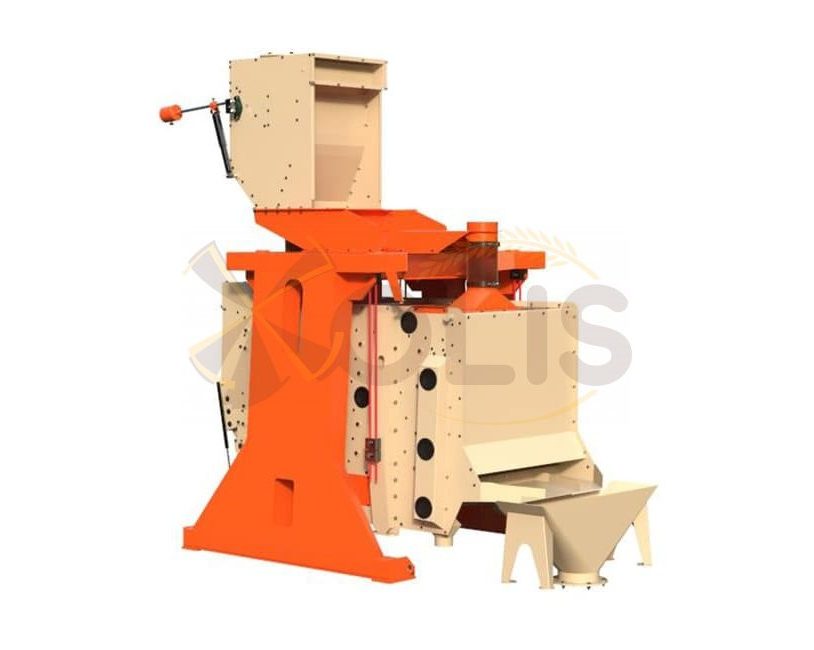

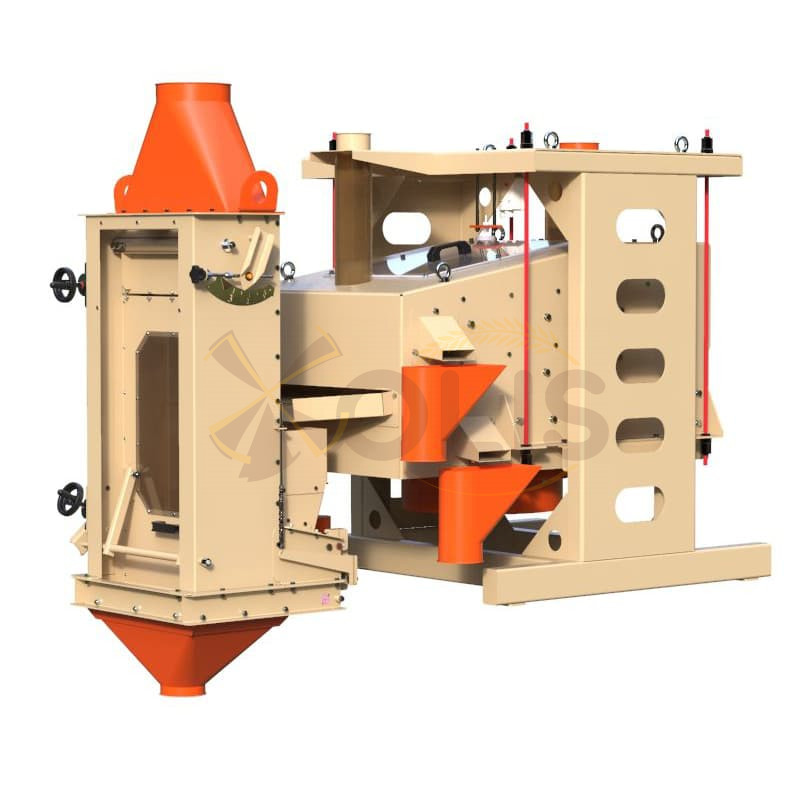

Screen Cleaner PSO-100

Screen cleaner flat-sieve type PSO-100 are designed for sorting and cleaning grain crops from impurities which differ from grain in geometric dimensions and aerodynamic properties, as well as for sorting and calibrating grain.

Product video

Product Description

Specifications

Аdvantages

Video/Photo

Additional Information

Описание

Описание

Олис

Олис

Purpose:

Screen cleaner flat-sieve type PSO-100 are designed for sorting and cleaning grain crops from impurities which differ from grain in geometric dimensions and aerodynamic properties, as well as for sorting and calibrating grain.

Screen cleaner flat-sieve type are equipped with an aspiration column KAO-1.0, an aspiration column AKL-60 and a funnel.

Principle of operation:

Composition: screen cleaner PSO-100, aspiration column AKL-60, control panel.

Description: the initial grain enters the aspiration column AKL-60 for the separation of light impurities, after which it enters the flat screen separator PSO-100, where the grain is cleaned from impurities which differ in geometric dimensions. The obtained fractions of purified grain and impurities are separately removed from the machine through outlet nozzles.

Composition: screen cleaner PSO-100, aspiration column AKL-60, aspiration column KAO-1.0, control panel.

Description: the initial grain enters the aspiration column AKL-60 for the separation of light impurities, after which it enters the flat-sieve separator PSO-100, where the grain is cleaned from impurities which differ in geometric dimensions. The cleaned grain is sent to the aspiration column KAO-1.0 for additional cleaning of light impurities. The obtained fractions of purified grain and impurities are separately removed from the machine through outlet nozzles.

Composition: screen cleaner PSO-100, aspiration column KAO-1.0, control panel.

Description: the initial grain enters the flat-sieve separator PSO-100, where the grain is cleaned of impurities which differ in geometric dimensions. The cleaned grain is sent to the aspiration column KAO-1.0 for additional cleaning of light impurities. The obtained fractions of purified grain and impurities are separately removed from the machine through outlet nozzles.

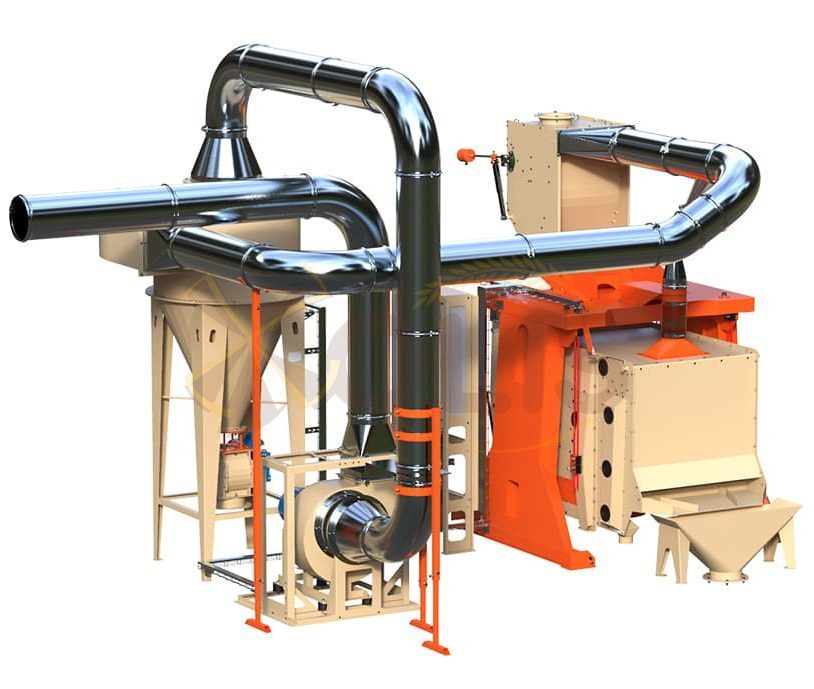

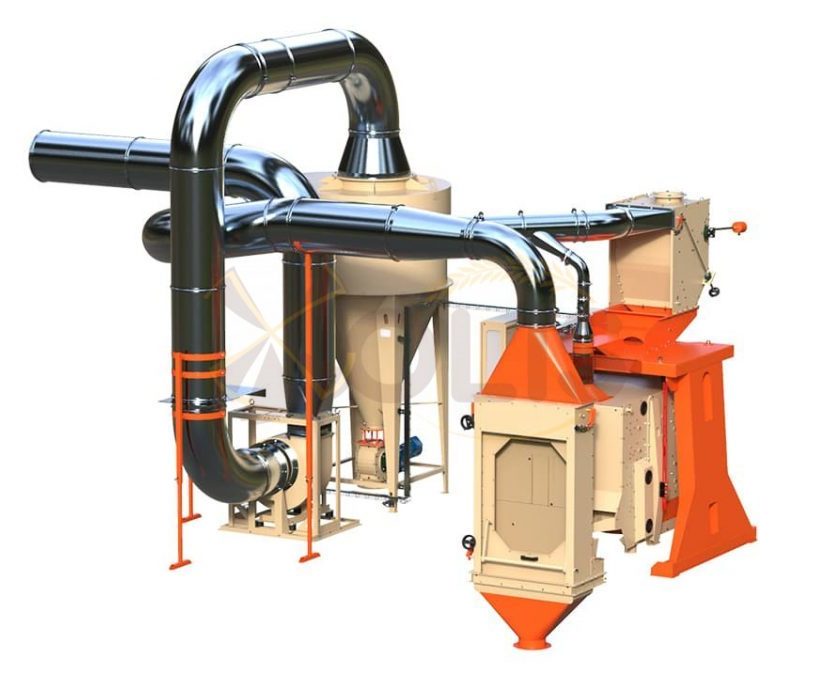

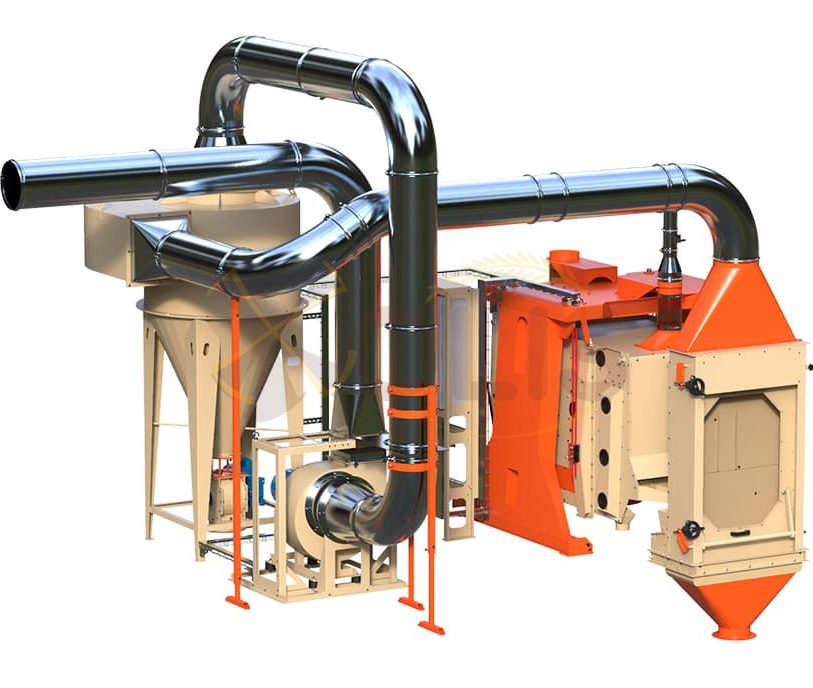

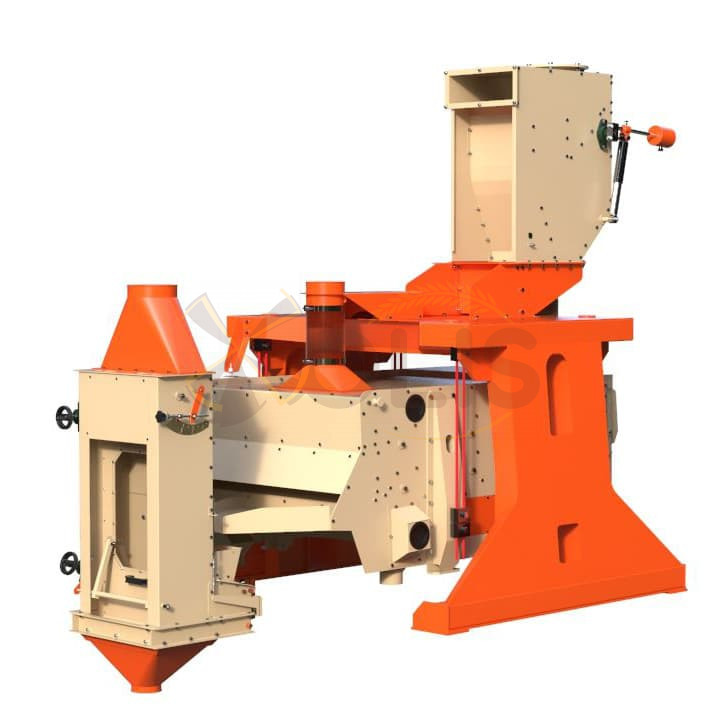

To simplify the installation work and ensure the most efficient operation of the sieve-air separator PSO-100, the aggregated solution PSO-100A has been developed.

Screen aggregate cleaner PSO-100A includes three configurations:

Composition: screen cleaner PSO-100, aspiration column AKL-60, cyclone with sluice gate and drive, fan, air ducts, control panel, cables, trays and ladders.

Composition: screen cleaner PSO-100, aspiration column AKL-60, aspiration column KAO-1.0, cyclone with sluice gate and drive, fan, air ducts, control panel, cables, trays and ladders.

Composition: screen cleaner PSO-100, aspiration column KAO-1.0, cyclone with sluice gate and drive, fan, air ducts, control panel, cables, trays and ladders.

Specifications

Выберите модель

| Model | PSO-100 | PSO-100А |

| Productivity, up to t/h: Primary cleaning (of wheat) | 30 | 30 |

| Working surface of sieves, m2 | 6 | 6 |

| Modification 01 | АКL-60 | АКL-60+АС+ЭС |

| Air consumption for aspiration, m3/h | 3700 | 3700 |

| Pre-installed electric power capacity, kW | 1,1 | 6,13 |

| Weight, kg | ||

| Overall dimensions, mm length width height |

2102 1820 2915 |

3096 4680 3639 |

| Modification 02 | АКL-60+КАО-1,0 | АКL-60+КАО-1,0+АС+ЭС |

| Air consumption for aspiration, m3/h | 8500 | 8500 |

| Pre-installed electric power capacity, kW | 1,1 | 9,71 |

| Weight, kg | ||

| Overall dimensions, mm length width height |

3330 1820 2915 |

3330 5335 4240 |

| Modification 03 | КАО-1,0 | КАО-1,0+АС+ЭС |

| Air consumption for aspiration, m3/h | 5300 | 5300 |

| Pre-installed electric power capacity, kW | 1,1 | 6,13 |

| Weight, kg | ||

| Overall dimensions, mm length width height |

2754 1802 2614 |

2755 1802 3670 |

Аdvantages

- Strong, durable construction;

- Installation symmetry of nozzles allows flexible installation of the separator in existing and new technological lines;

- Absence of contaminations;

- High efficiency of grain cleaning;

- Small dimensions;

- Ease of replacement of sieves and reliability of their cleaning;

- View of the pneumoseparation zone.

Videos

Photos

Выберите модель

| Model | PSO-100 | PSO-100А |

| Productivity, up to t/h: Primary cleaning (of wheat) | 30 | 30 |

| Working surface of sieves, m2 | 6 | 6 |

| Modification 01 | АКL-60 | АКL-60+АС+ЭС |

| Air consumption for aspiration, m3/h | 3700 | 3700 |

| Pre-installed electric power capacity, kW | 1,1 | 6,13 |

| Weight, kg | ||

| Overall dimensions, mm length width height |

2102 1820 2915 |

3096 4680 3639 |

| Modification 02 | АКL-60+КАО-1,0 | АКL-60+КАО-1,0+АС+ЭС |

| Air consumption for aspiration, m3/h | 8500 | 8500 |

| Pre-installed electric power capacity, kW | 1,1 | 9,71 |

| Weight, kg | ||

| Overall dimensions, mm length width height |

3330 1820 2915 |

3330 5335 4240 |

| Modification 03 | КАО-1,0 | КАО-1,0+АС+ЭС |

| Air consumption for aspiration, m3/h | 5300 | 5300 |

| Pre-installed electric power capacity, kW | 1,1 | 6,13 |

| Weight, kg | ||

| Overall dimensions, mm length width height |

2754 1802 2614 |

2755 1802 3670 |

- Strong, durable construction;

- Installation symmetry of nozzles allows flexible installation of the separator in existing and new technological lines;

- Absence of contaminations;

- High efficiency of grain cleaning;

- Small dimensions;

- Ease of replacement of sieves and reliability of their cleaning;

- View of the pneumoseparation zone.

Other goods in this category

X