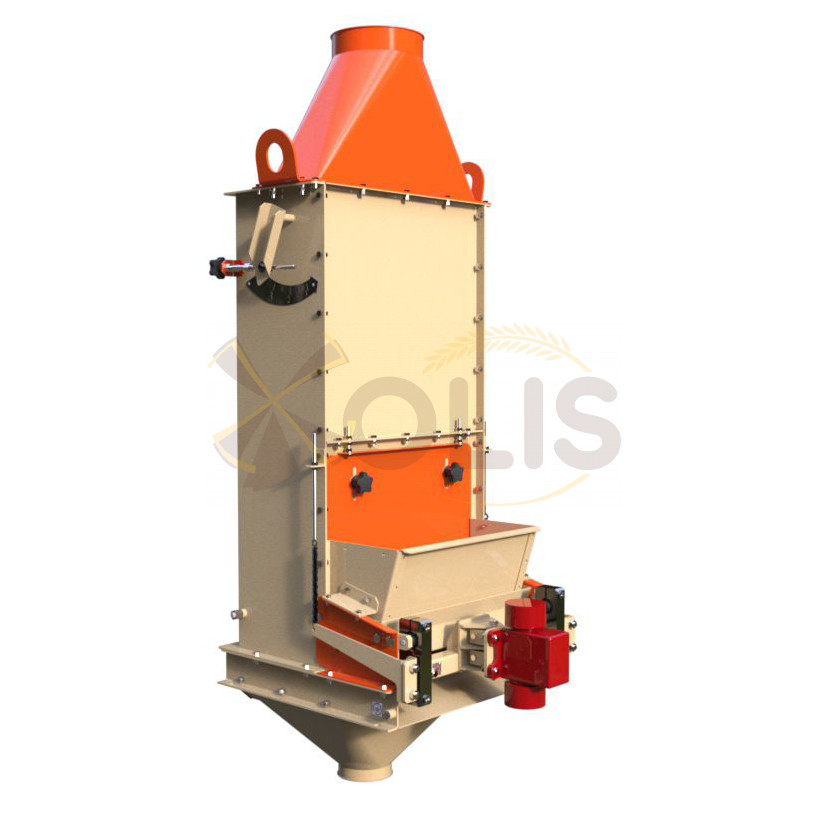

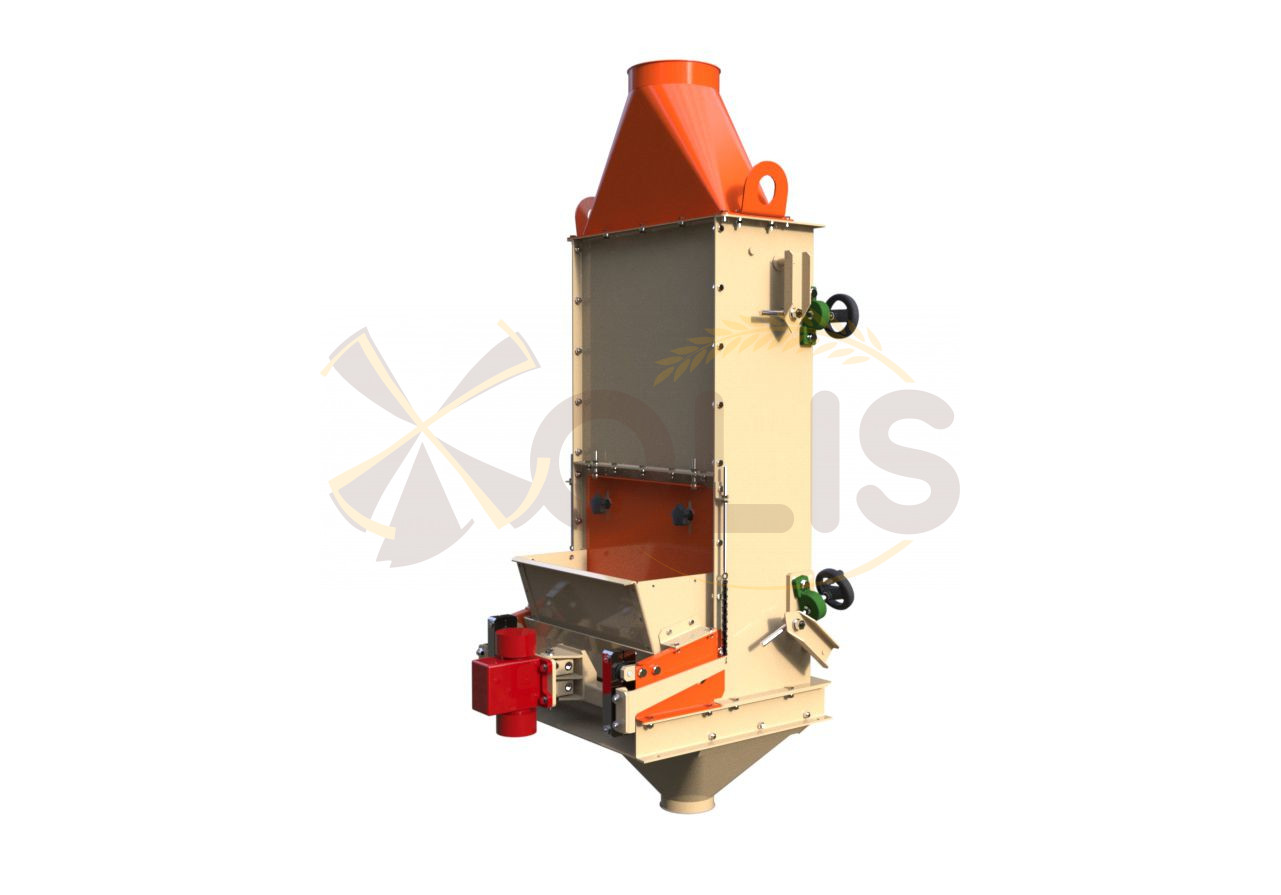

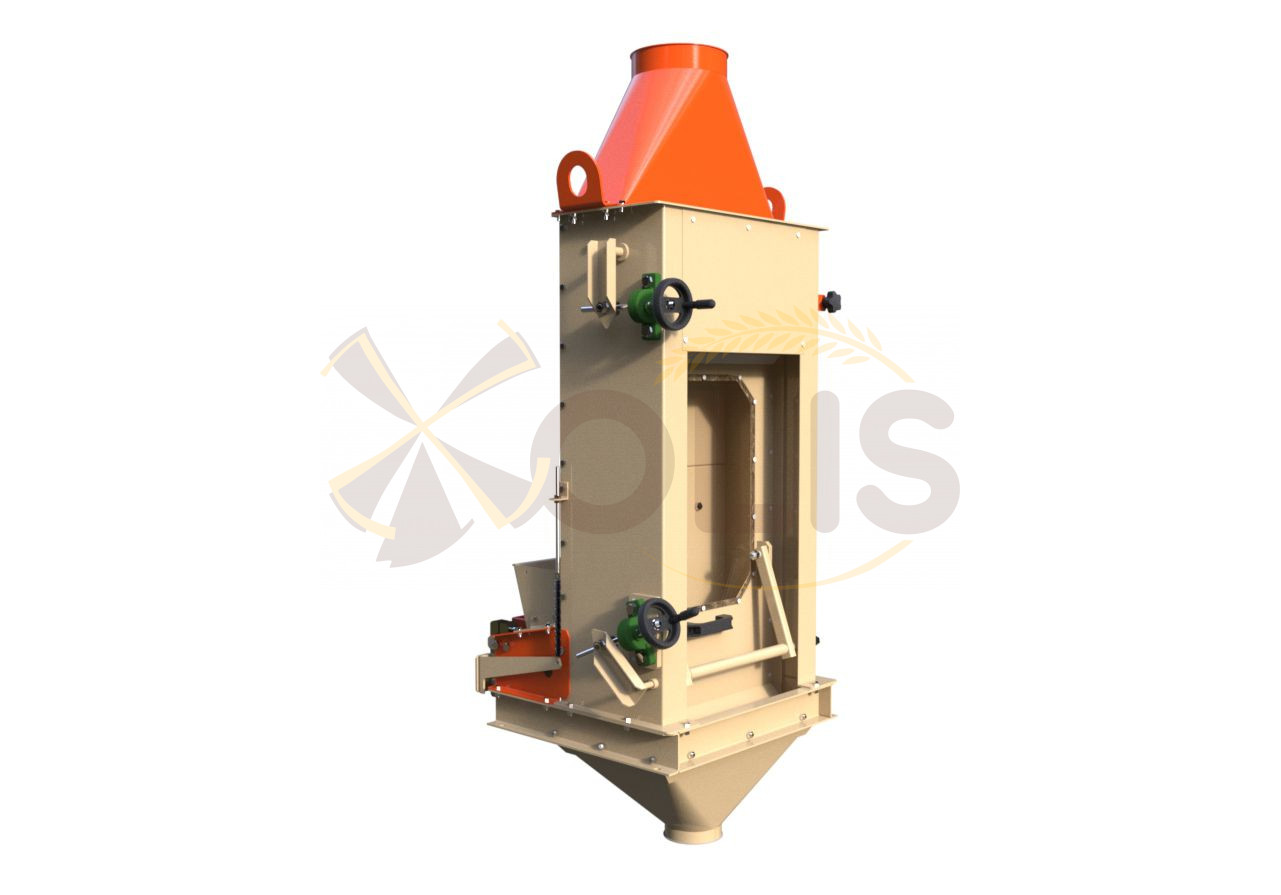

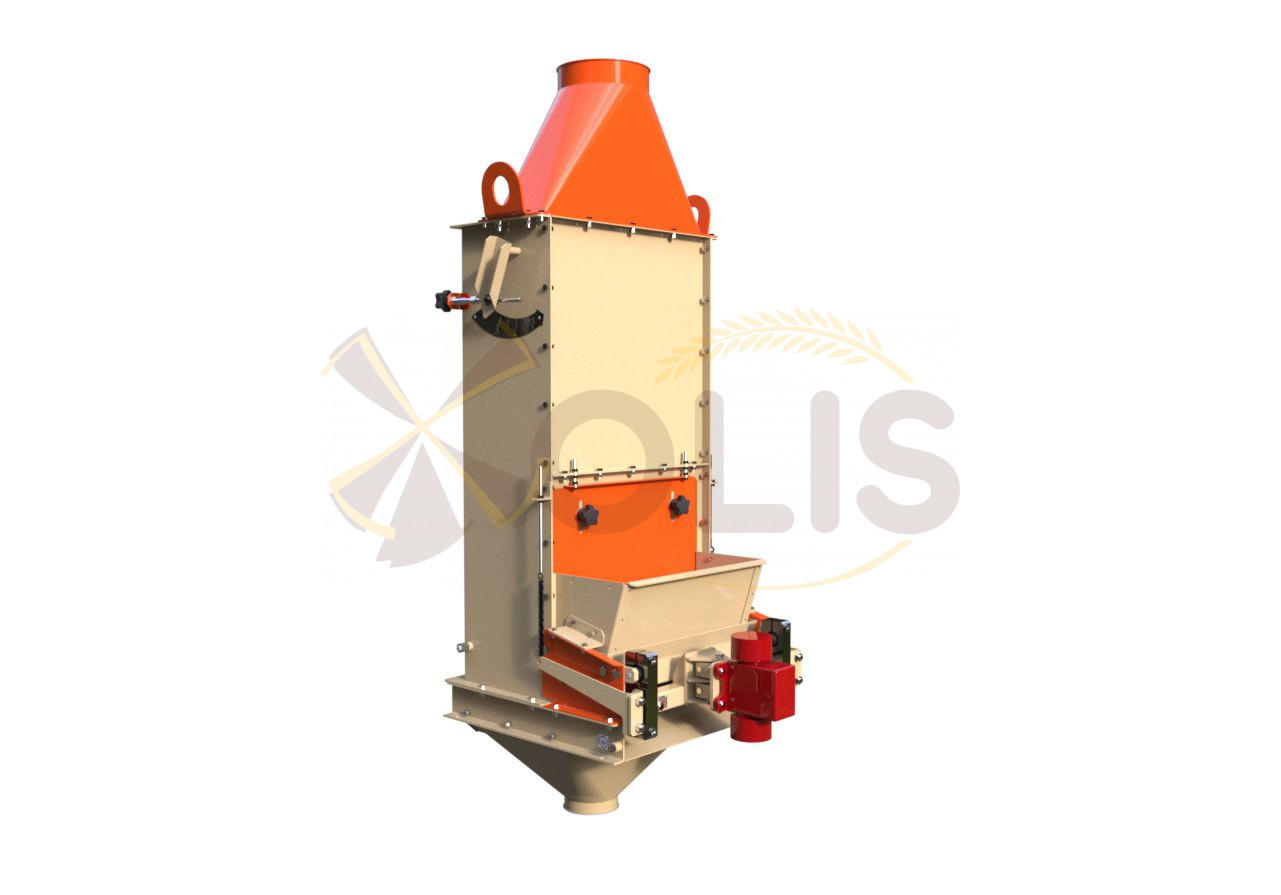

Aspiration channel КАО-0,6

Aspiration channel КАО-0,6 is intended for grain cleaning from impurities which differ in aerodynamic properties. It is used in grain elevators, groats, flour and feed mills.

Product Description

Specifications

Аdvantages

Video/Photo

Additional Information

Описание

Описание

Олис

Олис

Aspiration channel КАО-0,6 is intended for grain cleaning from impurities which differ in aerodynamic properties. It is used in grain elevators, groats, flour and feed mills.

Principle of operation:

The initial grain enters the receiving chamber, then onto the vibrating tray, which aligns the grain layer along the entire length of the air-separating channel. The movable wall in the lower part of the column is installed so that the layer of grain coming off the vibrating tray is almost horizontal, which contributes to optimal conditions of pneumatic separation. Light impurities together with air rise up the channel, entering the aspiration system, and the cleaned grain is discharged through the outlet.

Specifications

Выберите модель

| Model | КАО-0,6 |

| Productivity, t/h | 5 |

| Pre-installed electric power capacity, kW | 0,08 |

| Air consumption, m3/h | 300 |

| Weight, kg | 111 |

| Overall dimensions, mm length width height |

813 667 1674 |

Аdvantages

- High technological efficiency;

- High-quality cleaning of grain from light impurities thanks to the vibrating tray, which ensures uniform distribution of grain along the entire length of the pneumatic separating channel;

- Possibility to adjust the cross-section and shape of the air-separating channel;

- Use of components from leading European manufacturers.

Photos

Выберите модель

| Model | КАО-0,6 |

| Productivity, t/h | 5 |

| Pre-installed electric power capacity, kW | 0,08 |

| Air consumption, m3/h | 300 |

| Weight, kg | 111 |

| Overall dimensions, mm length width height |

813 667 1674 |

- High technological efficiency;

- High-quality cleaning of grain from light impurities thanks to the vibrating tray, which ensures uniform distribution of grain along the entire length of the pneumatic separating channel;

- Possibility to adjust the cross-section and shape of the air-separating channel;

- Use of components from leading European manufacturers.

Other goods in this category

X