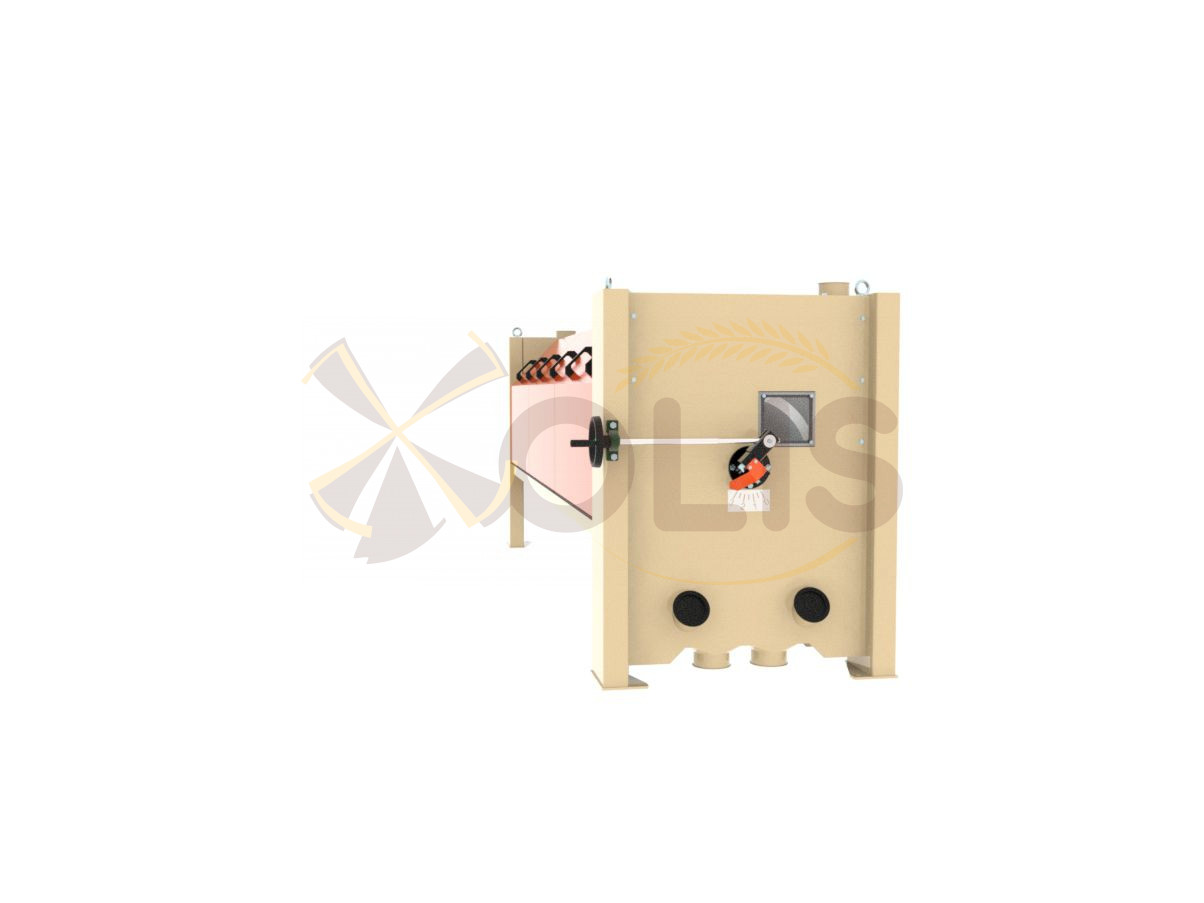

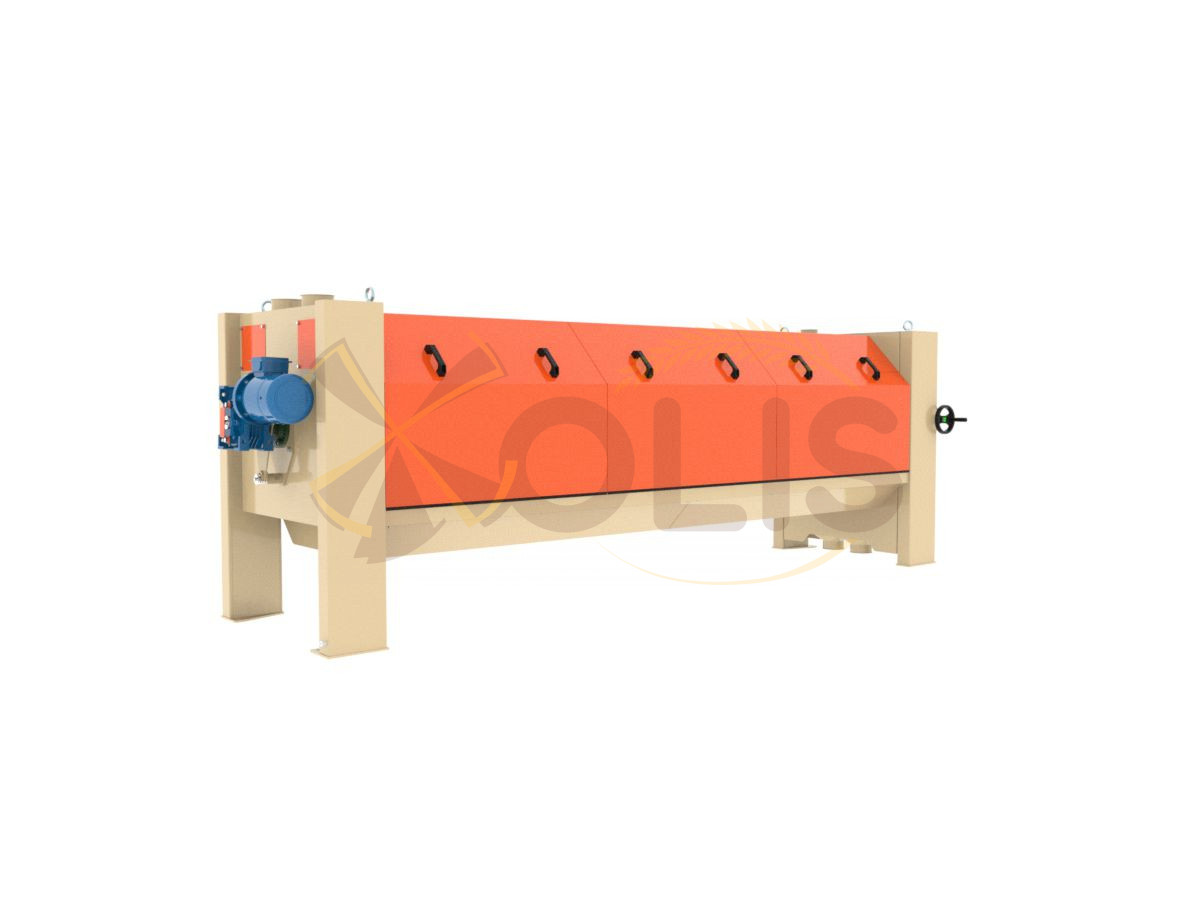

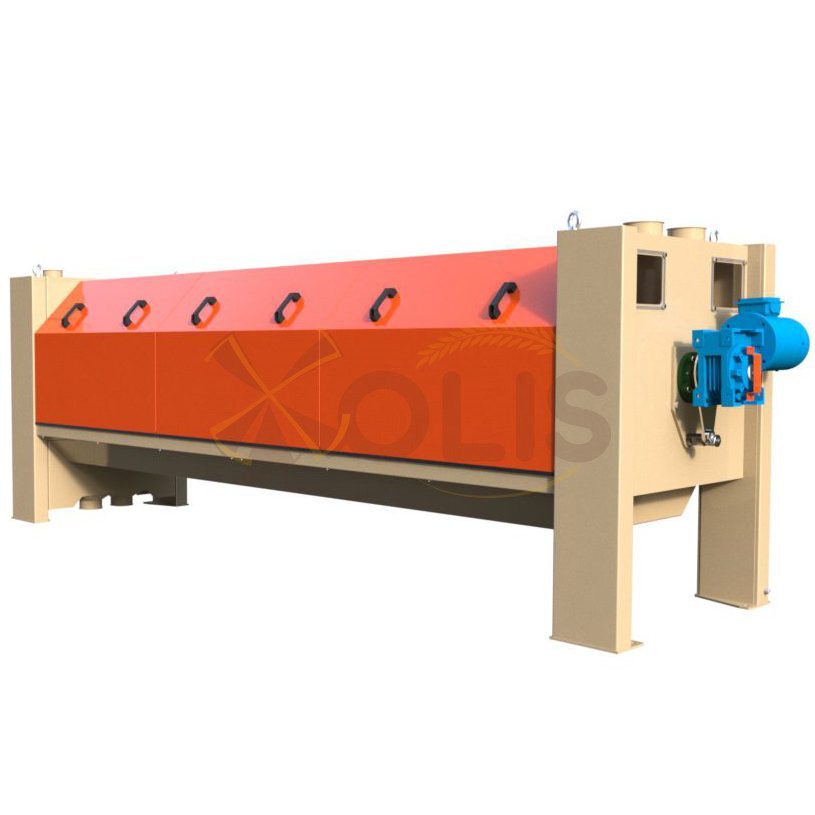

Indented Cylinder TCO-500

The indented cylinder is used in elevators, flour mills and groats mills to separate wild oat and cockle seeds from grain mixtures; at groats factories - for separating oats from barley and separating hulled and unhulled grains.

Purpose:

Indented cylinder TCO is intended for cleaning the grain of the main crop from the length of the admixture of wild oat. It is also used to sort cleaned grain by length.

Scope of application:

The indented cylinder is used in elevators, flour mills and groats mills to separate wild oat and cockle seeds from grain mixtures; at groats factories – for separating oats from barley and separating hulled and unhulled grains. And also at seed processing plants and corn seed calibration plants to select the largest grains from a mixture.

Operation description:

Main movable object of the indented cylinder is a cylinder with cells where short fractures (grain) are proceeded and long fractures (wild oat), which are longer than cells, are not proceeded into cells. The cell cylinder rotates and discharges long fractures on the first tray. Short fractures are discharged on the second tray. This is how the mixture is fractionated.

Specifications

| Model | TCO-500 | TCO-700 |

| Productivity up to, kg/h | 1900 | 4000 |

| Cleaning efficiency, not less, % | 80 | 80 |

| Pre-installed electric power capacity, kW | 0,75 | 1,1 |

| Power supply characteristics: Voltage, V Frequency, Hz |

380 50 |

380 50 |

| Air consumption for aspiration, m3/h | 300 | 600 |

| Aerodynamic resistance, Pa | 400 | 400 |

| Overall dimensions, mm length width height |

2800 1100 1400 |

4000 1200 1650 |

| Weight, not more, kg | 600 | 900 |

Аdvantages

- It is possible to mount both a separate machine and install two indented cylinder separators, one above the other, forming an indented cylinder separator block with sequential and parallel movement of the mixture;

- The operating cylinder is automatically set at an angle of 2º, which improves machine operation, ensuring mixture uniformity distribution over the operating cylinder;

- The collection tray can be adjusted in the range of 0-90º, which allows you to separate the mixture with maximum efficiency;

- Components from leading European manufacturers are used.

Photos

| Model | TCO-500 | TCO-700 |

| Productivity up to, kg/h | 1900 | 4000 |

| Cleaning efficiency, not less, % | 80 | 80 |

| Pre-installed electric power capacity, kW | 0,75 | 1,1 |

| Power supply characteristics: Voltage, V Frequency, Hz |

380 50 |

380 50 |

| Air consumption for aspiration, m3/h | 300 | 600 |

| Aerodynamic resistance, Pa | 400 | 400 |

| Overall dimensions, mm length width height |

2800 1100 1400 |

4000 1200 1650 |

| Weight, not more, kg | 600 | 900 |

- It is possible to mount both a separate machine and install two indented cylinder separators, one above the other, forming an indented cylinder separator block with sequential and parallel movement of the mixture;

- The operating cylinder is automatically set at an angle of 2º, which improves machine operation, ensuring mixture uniformity distribution over the operating cylinder;

- The collection tray can be adjusted in the range of 0-90º, which allows you to separate the mixture with maximum efficiency;

- Components from leading European manufacturers are used.