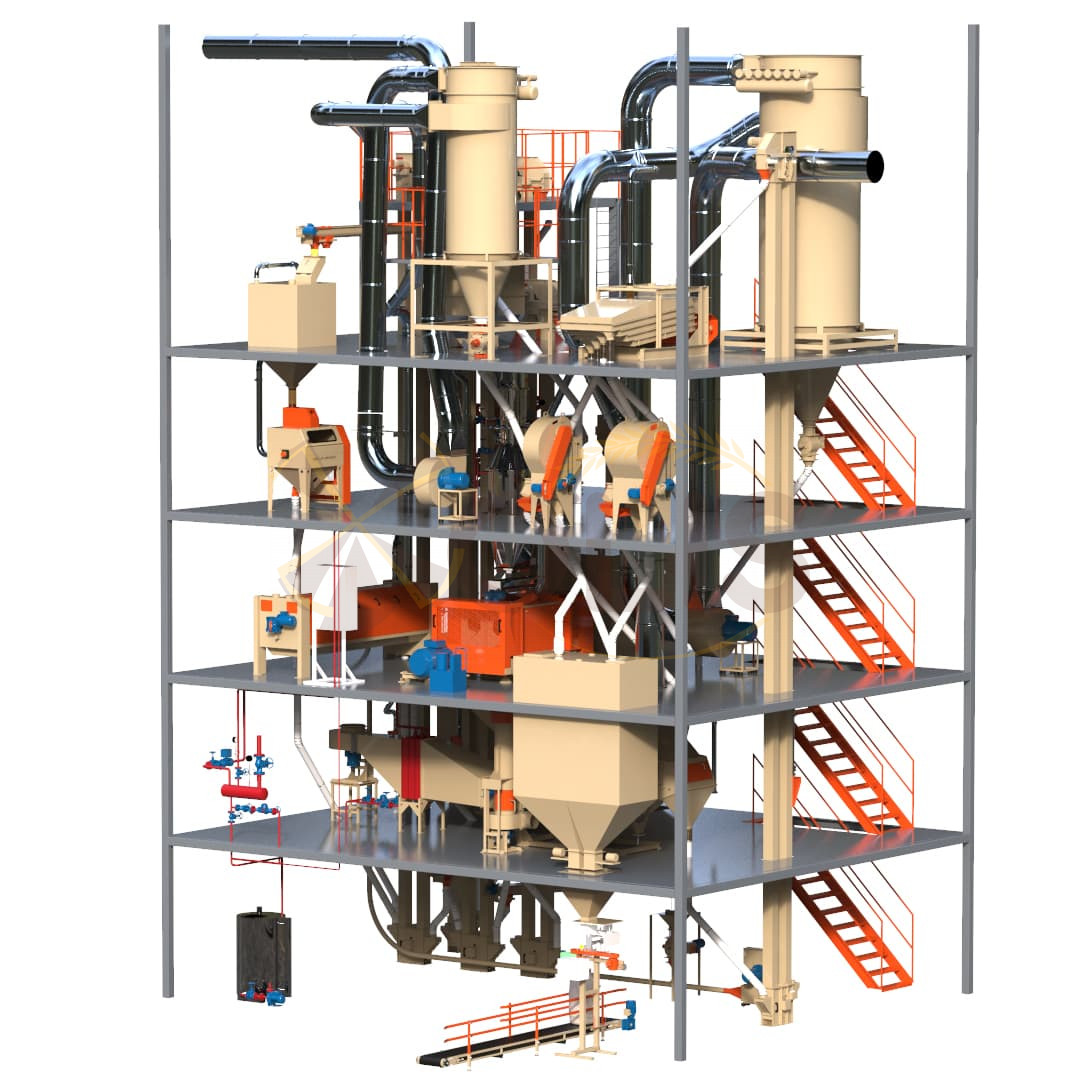

Flakes production plant with productivity 1,5 t/h

Purpose

The flakes production plant with productivity 1,5 t/h is designed to produce flakes from cereals. The equipment of the line ensures high quality and yield of flakes, which allows you to confidently meet the requirements of the market. The line was created according to the technology adopted to European countries, improved and supplemented with innovations from OLIS.

For the plant placement a 4-storey building with a floor height of at least 3 m and an area of each floor not less than 72 m2 is appropriate. In the absence of a appropriate building supporting steel frameworks for placement of equipment is recommended to perform in the form of a four-tiered frame up to 12 m high with dimensions of 6 m x 12 m in plan and set on their own foundations. In this case, the external enclosures (walls and roof) it is advisable to arrange on reinforced concrete structures and foundations, independent of the load-bearing equipment of steel structure. The expected height of the building – 15 m. The construction part can be supplemented by rooms for the operator’s room, shop laboratory, warehouses, etc.

As part of fulfilment individual project to the plant can be connected to a weighing and unloading station with the possibility of selecting flakes in bags and in small containers, as well as a warehouse for storing finished products.

The plant is working in automatic mode. Control of the line operation is provided by operator from the central control panel.

Аdvantages

- Flake quality meets the requirement of the highest standards.

- The line does not contain expensive imported equipment.

- The line is operated in automatic mode.

- Reliability of the equipment ensures trouble-free and long-lasting operation.

Photo

- Flake quality meets the requirement of the highest standards.

- The line does not contain expensive imported equipment.

- The line is operated in automatic mode.

- Reliability of the equipment ensures trouble-free and long-lasting operation.