Ukraine is one of the world's leading producers of grains, pulses and oilseeds. Therefore, the grain and grain processing industries play a key role in the structure of the country's agricultural sector and form the basis of the country's economic and food security. The level of efficiency of the grain and grain processing industries' development determines the welfare of the population, food security of the country, and export opportunities.

Despite the high volume of grain exports, Ukraine's future lies in increasing the production of processed grain products: traditional flour and flour products (bread, biscuits, pasta, etc.), cereals, flakes, breakfast cereals; and advanced processing products (gluten, starch, and their derivatives).

At the current stage of development of traditional grain processing facilities, there are aggregate and complete facilities, as well as facilities created according to individual projects.

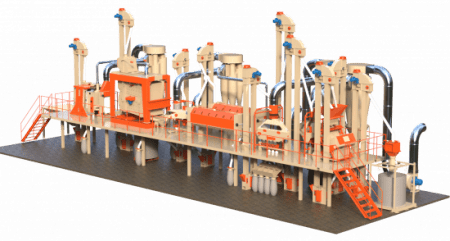

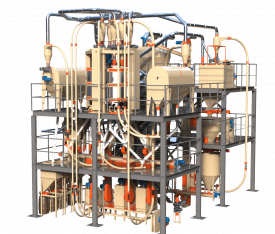

Unit production facilities are a set of equipment that implements a proven transport and technological scheme. In a factory, such equipment is assembled on a standard frame and equipped with all the necessary communications for start-up. As a rule, aggregate production facilities are small-scale production facilities that are mass-produced. The main advantage of unitised production is that they can be assembled quickly and put into operation in various adapted buildings with guaranteed results.

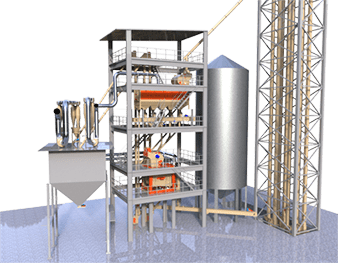

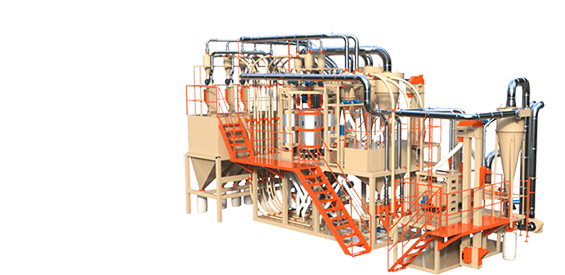

Prefabricated facilities are a set of machines and utilities that are mounted on pre-erected building structures at the intended place of operation and implement a standardised process flow. As a rule, prefabricated plants are medium and large-scale production facilities. Their distinctive feature is the need to erect building structures and carry out the entire range of installation and commissioning works at the place of operation. Since prefabricated plants implement solutions that have been proven in practice, the results of their implementation are quite predictable.

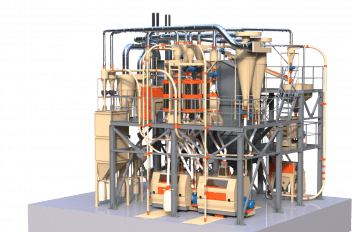

Customised production facilities are created in cases where the customer's requirements cannot be met by the range of aggregate and complete production facilities. As a rule, such cases include the need to "fit" the production into an existing building, to provide a particular technology with additional capabilities or versatility, to set a processing capacity that differs from a number of existing values, etc. The creation of customised production facilities includes a full range of design, construction, installation and commissioning works. A distinctive feature of such facilities is the extended implementation time, especially at the commissioning stage.